-26-

For Machines Mfg. Since 5/11

13" x 40" Heavy 13

®

EVS Lathe

P R E P A R A T I O N

3.

Clear away all tools and objects used during

assembly, lubrication, and preparation.

4.

Make sure that the chuck and jaws, if

installed, are secure (refer to

Chuck and

Faceplate Mounting

on

Page 31

).

Note:

If a chuck is not installed on the lathe, you

do not need to install one for this test.

5.

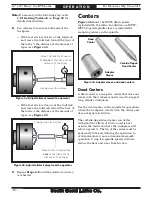

Push the STOP button on the control panel

(see

Figure 22

), and point the coolant nozzle

into the chip pan.

6.

Disengage the quick-change gearbox by

moving the feed range lever to the neutral

(middle) position, as shown in

Figure 23

.

7.

Move the spindle speed range lever so the

arrow on the hub points to the right (see

Figure 24

). This will make the lower spindle

speed range available.

Figure 22. Control panel components.

Spindle

Speed Dial

Power

Light

Coolant Pump

Switch

Jog

Button

STOP

Button

Figure 23. Feed range lever.

Low

Neutral

Feed Range Lever

High

Feed

Range Lever

DO NOT use the jog button to help mesh the

gears when changing spindle speeds or speed

range! Doing so could damage the gears and

connected components.

8.

Rotate the spindle speed dial (see

Figure 22

)

all the way counterclockwise to set it at the

lowest speed for startup.

9.

Turn the master power switch on the

electrical cabinet to the ON position.

10.

Reset the STOP button by twisting it

clockwise until it pops out. The power lamp

on the control panel should illuminate.

Note:

During the next step, you may need to use

the chuck key to rock the spindle back and

forth, while attempting to shift, so the gears

will mesh. If you do this, be sure to remove

the chuck key afterward.

Figure 24. Low spindle speed range selected.

Spindle

Range Lever

Arrow

Содержание SB1051

Страница 136: ...Printed In U S A TS14550...