XAV-60/E60

3

1.

SERVICING NOTES

............................................. 3

2. GENERAL

..................................................................

6

3. DISASSEMBLY

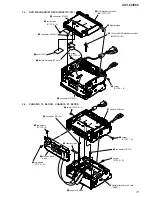

3-1. Disassembly Flow ........................................................... 12

3-2. Front Panel Block ........................................................... 12

3-3. DVD Mechanism Deck (MG-613C-187) ....................... 13

3-4. Chassis 1F Block, Chassis 2F Block .............................. 13

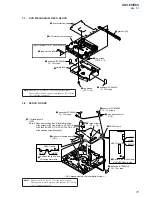

3-5. AUDIO Board ................................................................. 14

3-6. VISUAL Board ............................................................... 14

3-7. DVD Mechanism Deck Block ........................................ 15

3-8. SERVO Board ................................................................. 15

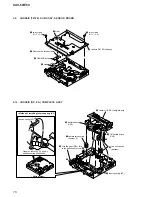

3-9. Chassis (T612Z) Sub Assy, SENSOR Board .................. 16

3-10. Chassis (OP, ZA) Complete Assy ................................... 16

4.

ELECTRICAL ADJUSTMENTS

........................ 17

5. DIAGRAMS

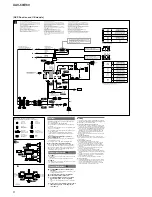

5-1. Block Diagram - SERVO Section - ................................ 20

5-2. Block Diagram - AUDIO Section - ................................. 21

5-3. Block Diagram - VIDEO Section - ................................. 22

5-4. Block Diagram - DISPLAY Section - ............................. 23

5-5. Block Diagram

- PANEL/POWER SUPPLY Section - ............................ 24

5-6. Printed Wiring Boards - SERVO Section - ..................... 26

5-7. Schematic Diagram - SERVO Section (1/3) - ................. 27

5-8. Schematic Diagram - SERVO Section (2/3) - ................. 28

5-9. Schematic Diagram - SERVO Section (3/3) - ................. 29

5-10. Printed Wiring Board - AUDIO Board (Side A) - .......... 30

5-11. Printed Wiring Board - AUDIO Board (Side B) - .......... 31

5-12. Schematic Diagram - AUDIO Board (1/4) - ................... 32

5-13. Schematic Diagram - AUDIO Board (2/4) - ................... 33

5-14. Schematic Diagram - AUDIO Board (3/4) - ................... 34

5-15. Schematic Diagram - AUDIO Board (4/4) - ................... 35

5-16. Printed Wiring Board

- VISUAL Board (Component Side) - ............................ 36

5-17. Printed Wiring Board

- VISUAL Board (Conductor Side) - .............................. 37

5-18. Schematic Diagram - VISUAL Board (1/5) - ................. 38

5-19. Schematic Diagram - VISUAL Board (2/5) - ................. 39

5-20. Schematic Diagram - VISUAL Board (3/5) - ................. 40

5-21. Schematic Diagram - VISUAL Board (4/5) - ................. 41

5-22. Schematic Diagram - VISUAL Board (5/5) - ................. 42

5-23. Printed Wiring Board - KEY Board -.............................. 43

5-24. Schematic Diagram - KEY Board - ................................ 43

5-25. Printed Wiring Board - LCD Board - .............................. 44

5-26. Schematic Diagram - LCD Board - ................................ 45

6.

EXPLODED VIEWS

6-1. Overall Section ............................................................... 69

6-2. Front Panel Section ......................................................... 70

6-3. Chassis 2F Section .......................................................... 71

6-4. Chassis 1F Section .......................................................... 72

6-5. DVD Mechanism Deck Section (MG-613C-187) .......... 73

7.

ELECTRICAL PARTS LIST

.............................. 74

Accessories are given in the last of the electrical parts list.

TABLE OF CONTENTS

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electro-

static break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(

Caution:

Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

NOTE THE IC4, IC11 AND IC13 ON THE SERVO

BOARD REPLACING

IC4, IC11 and IC13 on the SERVO board cannot exchange with

single. When these parts are damaged, exchange the entire mount-

ed board.

NOTE FOR REPLACING THE COMPLETE AUDIO

BOARD

If the complete AUDIO board was replaced, be sure to refer to

Technical News published separately.

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution:

The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

•

Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

•

Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Содержание XAV-60 - 6.1 Inch Avc

Страница 92: ...92 XAV 60 E60 MEMO ...