2

STR-KS1100

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK

0

OR DOTTED LINE

WITH MARK

0

ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

TABLE OF CONTENTS

1.

GENERAL

...................................................................

3

2.

DISASSEMBLY

2-1.

Disassembly Flow ...........................................................

5

2-2.

Case (SL07) .....................................................................

5

2-3.

Front Panel Assy ..............................................................

6

2-4.

HDMI Board ....................................................................

6

2-5.

MAIN Board ....................................................................

7

3.

TEST MODE

..............................................................

8

4.

DIAGRAMS

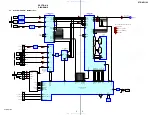

4-1.

Block Diagram – MAIN Section – .................................

9

4-2.

Block Diagram – AMP Section – ................................... 10

4-3.

Block Diagram – HDMI Section – ................................. 11

4-4.

Block Diagram

– PANEL/POWER SUPPLY Section – ........................... 12

4-5.

Schematic Diagram – I/O Board – ................................. 15

4-6.

Printed Wiring Board

– I/O Board (Component Side) – ................................... 16

4-7.

Printed Wiring Board

– I/O Board (Conductor Side) – ...................................... 17

4-8.

Printed Wiring Board

– MAIN Board (Component Side) – ............................... 18

4-9.

Printed Wiring Board

– MAIN Board (Conductor Side) – ................................. 19

4-10. Schematic Diagram – MAIN Board (1/8) – ................... 20

4-11. Schematic Diagram – MAIN Board (2/8) – ................... 21

4-12. Schematic Diagram – MAIN Board (3/8) – ................... 22

4-13. Schematic Diagram – MAIN Board (4/8) – ................... 23

4-14. Schematic Diagram – MAIN Board (5/8) – ................... 24

4-15. Schematic Diagram – MAIN Board (6/8) – ................... 25

4-16. Schematic Diagram – MAIN Board (7/8) – ................... 26

4-17. Schematic Diagram – MAIN Board (8/8) – ................... 27

4-18. Printed Wiring Boards – DCAC/SPEAKER Boards – ... 28

4-19. Schematic Diagram – DCAC/SPEAKER Boards – ....... 29

4-20. Printed Wiring Board – HDMI Board – ......................... 30

4-21. Schematic Diagram – HDMI Board – ............................ 31

4-22. Printed Wiring Boards – PANEL Section – .................... 32

4-23. Schematic Diagram – PANEL Section – ........................ 33

5.

EXPLODED VIEWS

5-1.

Overall Section ................................................................ 49

5-2.

MAIN Section ................................................................. 50

6.

ELECTRICAL PARTS LIST

................................ 51

General

Power requirements

Power output (DIGITAL MEDIA PORT)

DC OUT:

5 V, 700 mA

Power consumption

Power consumption (during standby mode)

0.3 W

Dimensions (w/h/d) (Approx.)

430

×

66.5

×

335 mm

including projecting parts

and controls

Mass (Approx.)

3.6 kg

Area code

Power requirements

CEL, CEK

230 V AC, 50/60 Hz

Area code

Power consumption

CEL, CEK

110 W

Design and specifications are subject to

change without notice.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

•

Unleaded solder melts at a temperature about 40 ˚C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 ˚C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

Strong viscosity

Unleaded solder is more viscou-s (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

Notes on chip component replacement

•

Never reuse a disconnected chip component.

•

Notice that the minus side of a tantalum capacitor may be

damaged by heat.

www. xiaoyu163. com

QQ 376315150

9

9

2

8

9

4

2

9

8

TEL 13942296513

9

9

2

8

9

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL 13942296513 QQ 376315150 892498299