29

5-14. ERROR RATE CHECK

5-14-1. CD Error Rate Check

Checking Procedure :

1. Load a check disc (MD) TDYS-1.

2. Rotate the AMS knob and display “CPLAY1 MODE”.

3. Press the YES button twice and display “CPLAY1 MID”.

4. The display changes to “C1 =

AD =

”.

5. Check that the C1 error rate is below 20.

6. Press the MENU/NO button, stop playback, press the

A

but-

ton, and remove the test disc.

5-14-2. MO Error Rate Check

Checking Procedure :

1. Load a continuously recorded test disc (MDW-74/GA-1).

(Refer to “5-5. Using the Continuously Recorded Disc”.)

2. Rotate the AMS knob and display “CPLAY1 MODE”.

3. Press the YES button and display “CPLAY1 MID”.

4. The display changes to “C1 =

AD =

”.

5. If the C1 error rate is below 20, check that ADER is 00.

6. Press the MENU/NO button, stop playback, press the

A

but-

ton, and remove the test disc.

5-15. FOCUS BIAS CHECK

Change the focus bias and check the focus tolerance amount.

Checking Procedure :

1. Load a continuously recorded test disc (MDW-74/GA-1).

(Refer to “5-5. Using the Continuously Recorded Disc”.)

2. Rotate the AMS knob and display “CPLAY1 MODE”.

3. Press the YES button twice and display “CPLAY1 MID”.

4. Press the MENU/NO button when “C1 =

AD =

” is

displayed.

5. Rotate the AMS knob and display “FBIAS CHECK”.

6. Press the YES button and display “

/

c =

”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADR, and the 2 digits after [c =] indicate the

focus bias value.

Check that the C1 error is below 20 and ADER is below 2.

7. Press the YES button and display “

/

b =

”.

Check that the C1 error is below 100 and ADER is below 2.

8. Press the YES button and display “

/

a =

”.

Check that the C1 error is below 100 and ADER is below 2

9. Press the MENU/NO button, next press the

A

button, and

remove the continuously recorded disc.

Note 1 :

If the C1 error and ADER are above other than the speci-

fied value at points a (step 8. in the above) or b (step 7. in

the above), the focus bias adjustment may not have been

carried out properly. Adjust perform the beginning again.

5-16. AUTO GAIN CONTROL OUTPUT LEVEL

ADJUSTMENT

Be sure to perform this adjustment when the Optical pick-up is re-

placed.

If the adjustment results becomes “Adjust NG!”, the Optical pick-

up may be faulty or the servo system circuits may be abnormal.

5-16-1. CD Auto Gain Control Output Level Adjustment

Adjusting Procedure :

1. Insert the check disc (MD) TDYS-1.

2. Rotate the AMS knob to display “AG Set (CD)”.

3. When the YES button is pressed, the adjustment will be

performed automatically.

“Complete!!” will then be displayed momentarily when the value

is recorded in the non-volatile memory, after which the display

changes to “AG Set (CD)”.

4. Press the

A

button to remove the disc.

5-16-2. MO Auto Gain Control Output Level Adjustment

Adjusting Procedure :

1. Insert the reference disc (MDW-74/GA-1) for recording.

2. Rotate the AMS knob to display “AG Set (MO)”.

3. When the YES button is pressed, the adjustment will be

performed automatically.

“Complete!!” will then be displayed momentarily when the value

is recorded in the non-volatile memory, after which the display

changes to “AG Set (MO)”.

4. Press the

A

button to remove the disc.

Содержание MDS-JE440 - Md Player

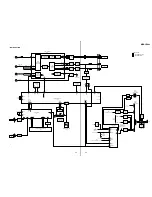

Страница 42: ...MDS JE440 42 42 6 10 SCHEMATIC DIAGRAM MAIN SECTION 3 3 See page 47 for IC Block Diagrams ...

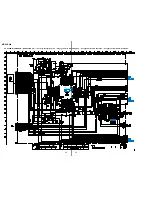

Страница 43: ...MDS JE440 43 43 6 11 PRINTED WIRING BOARD POWER SECTION ...

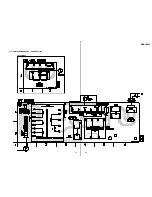

Страница 44: ...MDS JE440 44 44 6 12 PRINTED WIRING BOARD DISPLAY SECTION ...

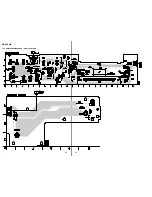

Страница 45: ...MDS JE440 45 45 6 13 SCHEMATIC DIAGRAM DISPLAY SECTION See page 34 for Waveforms ...