22

SECTION 6 - POWER UNIT SERVICE

6.1 REPLACEMENT PARTS

To retain the quality of your mower, use Genuine

SNAPPER Replacement Parts only! Contact your local

SNAPPER dealer for parts and service assistance. For

the correct part or information for your mower, always

mention Model and Serial Number of Power Unit and

Mower Attachment. We recommend returning your

mower to an authorized SNAPPER Dealer on a yearly

basis for inspection and addition of any new devices

which might upgrade the performance and safety of

your mower. For the nearest SNAPPER Dealer, check

the Yellow Pages under the heading LAWN MOWERS.

For Engine Parts and Service, look for the Engine

Manufacturer’s Dealers under the heading ENGINES-

Gasoline. For transmission parts and service, look for

Tecumseh Engines & Transmission under Engines-

Gasoline.

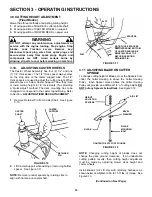

WARNING

DO NOT attempt any maintenance, adjustments or

service with the engine running. Stop engine. Stop

blades. Lock Traction Levers. Remove key.

Disconnect spark plug wires from spark plugs and

secure wires away from spark plugs. Engine and

components are HOT. Avoid serious burns, allow all

parts to cool before working on machine.

NOTE: All mid-size mowers should be tilted with

engine carburetor side UP.

6.2 TRANSMISSION PARTS & SERVICE

For the nearest Peerless Transmission Dealer, check

the Yellow Pages under heading, Engine-Gasoline.

Look for Tecumseh Engine and Transmission under

Engine-Gasoline.

6.2.1. GENERAL TRANSMISSION SERVICING

1. GENERAL TRANSMISSION SERVICING

Introduction:

The following service procedures should be

understood and practiced whenever service must

be performed on a Peerless MST 205 Series

Transmission.

2. Before removing transmission from mower, make

sure another part of machine is not causing

problem, look for:

a) Loose drive belt.

b) Sheared keys in pulleys.

c) Oil saturated drive belts.

d) Transmission shift lever secure.

6.2.2. TRANSMISSION

The Peerless MST 205 Series Transmission requires

no routine maintenance. Return machine to an

authorized Snapper dealer for service, maintenance or

problems.

6.2.3. TRANSMISSION

LUBE

The transmission is permanently sealed. But, lubrication

can be added if leakage should occur. The transmission

case holds 16 ounces of 80W-90 gear oil. To Lubricate:

1. Remove transmission switch wire plug and remove

the transmission interlock switch. Remove the fiber

washer seated on switch.

2. Transmission oil is added through the switch hole.

3. Install new fiber washer, part number 2-9662, onto

switch. Install switch into transmission and tighten

securely. Attach wire plug onto switch.

Содержание SPE361

Страница 8: ...8 SECTION 2 SAFETY MESSAGES AND SYMBOLS IMPORTANT SAFETY AND OPERATING INSRUCTIONS...

Страница 26: ...26 SECTION 8 ELECTRICAL FIGURE 8 1...

Страница 28: ...28 PRIMARY MAINTENANCE...

Страница 29: ...29 PRIMARY MAINTENANCE...

Страница 30: ...30 PRIMARY MAINTENANCE...

Страница 31: ...31 PRIMARY MAINTENANCE...

Страница 32: ...32 NOTES...

Страница 33: ...33 NOTES...