11

SECTION 3 - OPERATING INSTRUCTIONS

3.1 BEFORE OPERATING

Be Thoroughly familiar with all controls and how to use

them before operating the machine. Know beforehand

how to STOP the Traction Wheel Drives, Mower Blades

and Engine in preparation for possible emergencies.

3.2 STOPPING MACHINE

1. To STOP forward or reverse motion, firmly squeeze

both Traction Levers towards the handle and hold.

Using your right thumb, push Traction Lock forward

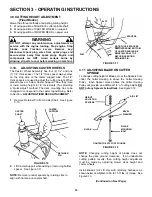

to the “Locked” position and hold. See Figure 3.1.

2. Make sure that the Traction Lock has fully engaged

both the right and left Traction Levers.

3. Release Traction Levers slowly and with caution.

Remove thumb from Traction Lock.

4. Move Transmission Shift Lever to “Neutral”.

5. Move Blade Clutch Switch down to the OFF position.

See Figure 3.1.

6. Move Engine Speed Control Lever to SLOW (turtle)

position. See Figure 3.1.

7. STOP ENGINE by turning Key Switch to “Stop”

position. Remove key. See Figure 3.1.

FIGURE 3.1

WARNING

When the Operator’s Presence Control (OPC) is

released, the machine will continue to operate a few

feet. DO NOT use this Operator’s Presence Control

(OPC) to routinely stop the machine.

3.3 PRE-START CHECK LIST

Make the following checks and perform the services as

required before each start-up:

1. If required, make cutting height adjustments. Refer

to Section “CUTTING HEIGHT ADJUSTMENT”..

2. Check tires and adjust inflation pressure as needed.

Inflate front tires to 25 psi and rear tires to 12-15 psi.

3. Check Guards, Deflector, and Belt Covers to make

sure all are in place and secure.

4. Check Condition of Cutter Deck Belt(s). If dam-

aged, replace with original part. Refer to Section

“CUTTER DECK BELT REMOVAL”.

5. Inspect condition of cutter blades. If worn or

damaged, replace before operating machine. Refer

to Section “Cutter Blade Service”.

6. Clean Interior and Exterior Surfaces of cutting deck

and clean Engine of any accumulation of dirt, grass,

oil, etc. Keep Engine air intake screens and cooling

fins clear at all times.

7. Check Engine Oil and add oil as needed to bring

level up to (but not over) the FULL mark. (Refer to

Engine manual for oil specifications).

8. Add Fuel to tank after pushing the Mower outside

where fumes can be dissipated. Make sure Fuel

Tank Cap is tightened after refueling. (Refer to

Engine manual for fuel specifications).

NOTE: DO NOT add fuel while engine is running or hot.

Use fresh, clean, lead-free gasoline. DO NOT use

gasoline that has been stored for long periods. Leaded

gasoline or gasohol is NOT recommended.

3.4 STARTING & OPERATING

3.4.1. ENGINE: START ENGINE AS FOLLOWS:

1. Turn Fuel Shut-Off Valve to the OPEN position. See

Figure 3.2.

2. Pull both Traction Levers firmly rearward towards the

handle. Using the Traction Lock Lever, lock both

Traction Levers in the Traction “Locked” position.

Make sure that the Traction Lock has fully engaged

both Traction Levers. See Figure 3.2.

3. Place Transmission Shift Lever in

NEUTRAL (N)

position. See Figure 3.3

4. Move Blade Clutch Switch down to the OFF position.

See Figure 3.1.

5. Move Engine Speed Control Lever to the CHOKE

position. See Figure 3.4.

6.

Turn Key Switch to RUN position.

RIGHT HAND

TRACTION

LEVER

BLADE CLUTCH

SWITCH

SHOWN IN OFF

POSITION

ENGINE

SPEED

CONTROL

TRACTION LOCK

SHOWN IN TRACTION

LOCKED POSITION

KEY SWITCH

SHOWN IN

STOP POSITION

Содержание SPE361

Страница 8: ...8 SECTION 2 SAFETY MESSAGES AND SYMBOLS IMPORTANT SAFETY AND OPERATING INSRUCTIONS...

Страница 26: ...26 SECTION 8 ELECTRICAL FIGURE 8 1...

Страница 28: ...28 PRIMARY MAINTENANCE...

Страница 29: ...29 PRIMARY MAINTENANCE...

Страница 30: ...30 PRIMARY MAINTENANCE...

Страница 31: ...31 PRIMARY MAINTENANCE...

Страница 32: ...32 NOTES...

Страница 33: ...33 NOTES...