10

INSTALLATION

Make sure that the supply voltage is 230 volt and a minimum

of 30 amp service. When mounting a plug, make sure it has

an adequate capacity, and that the

"yellow/green

conductor"

of the power supply cable is connected to the

ground or “earth” terminal. The blue and brown wires need

to be connected to the “hot leg” terminals

WARNING

Only skilled personnel should install the machine. All

connections must be carried out according to current

regulations.

See complete listing of safety messages at the beginning of

this manual.

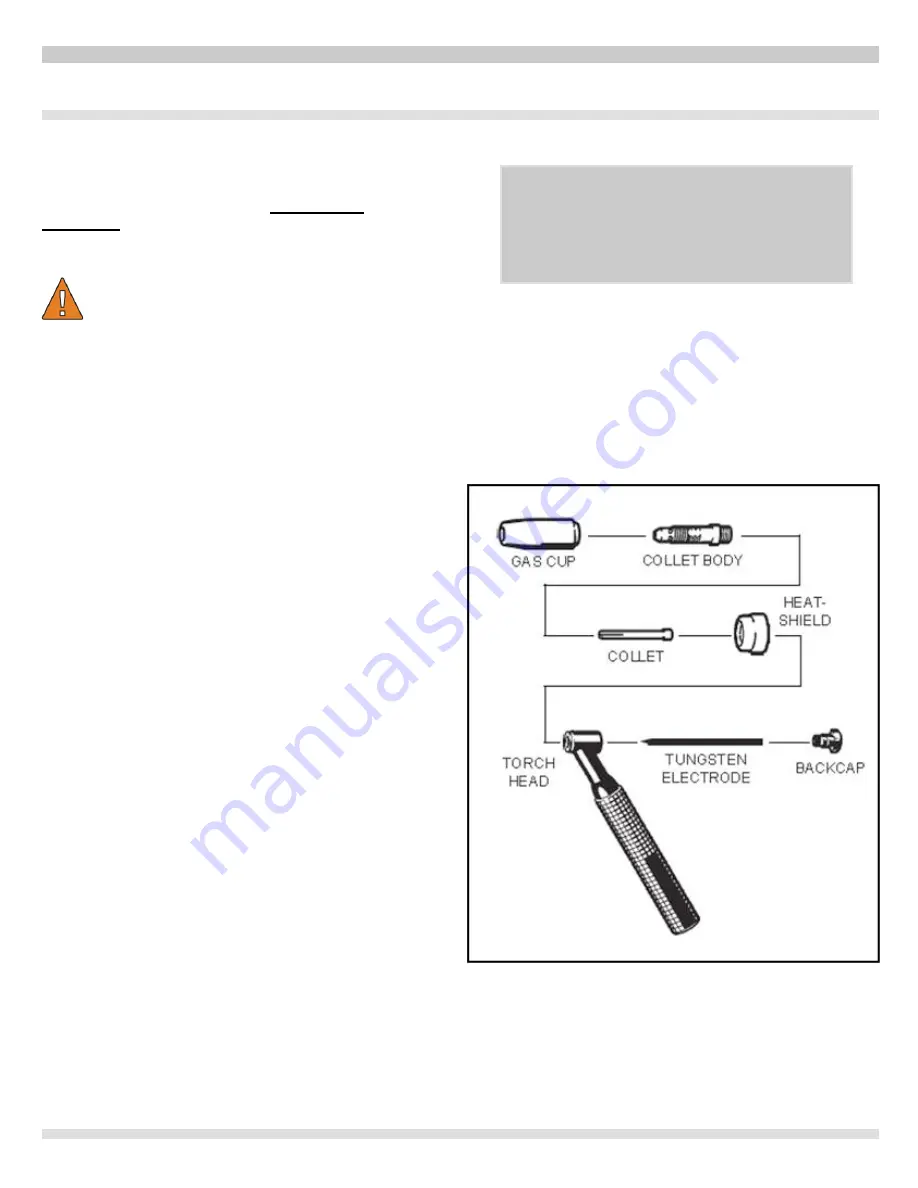

TORCH HEAD ASSEMBLY

1. Select the size tungsten electrode to be used

– see table A

2. Make sure the Teflon heat shield is in place.

3. Locate the matching size Collet and Collet body.

4. Drop the Collet, slit-end down, into the Collet body.

5. Screw assembly into the torch head, heat shield side,

and tighten firmly.

6. Install a Gas cap, screw into place seating the cup

against the Teflon heat shield.

7. Insert tungsten electrode, prepped end first, thru the

torch head, Collet and center hole of the Collet body.

8. Allow tungsten electrode to extend past the cup ~ 3

times the electrode diameter.

9. Screw Backcap into torch head and tighten firmly.

Review the exploded view on the next page.

ASSEMBLING THE UNIT/START UP GUIDE

For detailed machine start up see

“SETTING UP YOUR NEW

TIG WELDING SYSTEM”

.