π = 3.14. You can use an rpm chart for selected diameters of cutting tools at

different cutting speeds.

Change Speeds by selecting the belt location and turning the speed dial

Feeds

Set the direction of feed before you begin milling. Up milling, or conventional

milling, is when the direction of feed is opposite to the direction of cutter

rotation. Down milling, or climb milling, is when the direction of feed is the

same as the direction of cutter rotation.

Up Milling

In up milling, forces on the work piece tend to pull it out of the vise or fixture

holding it, so fasten it securely. These forces also push the work piece away

from the cutter, which eliminates backlash. Up milling is advised for milling

cast iron, softer steels, and other ductile materials. In general, it's how you

should perform milling operations.

Down Milling

Down milling usually produces good surface finishes because chips do not

sweep back into the cut. Setups are more rigid, an advantage when cutting

thin work pieces held in a vise or work pieces held in a magnetic chuck.

Down milling also produces straighter cuts. We recommend down milling

when using carbide cutters because there is less wear on the cutting tool. In

general, however, avoid it because of the backlash problems associated with

it.

Feed Rates

Your feed rates should be as high as your machine, cutting tool, work holding

method, and work piece can tolerate while giving a good finish. Feed rate is

usually given in inches per minute (ipm). You determine feed rate by the

speed of the cutter in rpm and the number of teeth in the cutter.

There are many factors to consider in selecting the feed per tooth, and there

is no easy formula to follow. Here are several principles to guide you:

• Use the highest feed rate conditions allow

• Avoid using a feed rate below 0.001” per tooth

• Harder materials required lower feed rates than softer materials

• Feed wider, deeper cuts more slowly than narrow, shallow cuts

• Slower feed rate gives a better surface finish

• Never stop the feed before finishing the cut

26

Содержание MI-409MZ

Страница 1: ...Smithy MI 409MZ Operator s Manual 1 ...

Страница 31: ...Chapter 13 Parts Diagrams in work ...

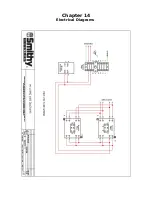

Страница 32: ...Chapter 14 Electrical Diagrams ...

Страница 33: ......