Chapter 7

Preparing the MI-409MZ for Operation

Overview

Before using your new machine, it is important to make sure it is top working

condition and is properly lubricated. The section of the manual, will walk you

through lubrication and gib adjustments.

Cleaning and lubricating the machine

Smithy machines are shipped with a protective grease coating. To remove it,

spray on WD-40, let it sit for a few minutes, and wipe it off with rags. Use a

brush and noncorrosive kerosene or white mineral spirits to clean hard to

reach places.

Give special attention to the lead screw. Use a brush or cotton string to clean

down into the threads.

Once it's cleaned, your Smithy is ready for lubricating. Do this carefully and

thoroughly before starting the machine. Use pressure oil can and good

quality SAE 30 weight machine oil on the bearings and headstock.

The mill head has an oil site gauges on the right side of the mill head. The oil

level should be half way up the site gauge. Use a good quality 30wt or 10w

30 wt oil.

There are oil buttons located in numerous locations on the carriage, table,

tool post and tail stock. These should be oiled on a daily basis.

When the machine is not in use, it is recommended that a thin coat of oil be

applied to all exposed metal parts to protect the surfaces from corrosion.

Adjusting the Mill – Tightening the Gibs

The objective of adjusting the gibs is to eliminate as much play in the X, Y,

and Z axis as possible without having the tightness of the gib interfere with

their movement and cause a decrease in the accuracy and performance of

the machine due to excessive friction.

Before beginning, make sure the ways are clean and well-oiled

.

19

Содержание MI-409MZ

Страница 1: ...Smithy MI 409MZ Operator s Manual 1 ...

Страница 31: ...Chapter 13 Parts Diagrams in work ...

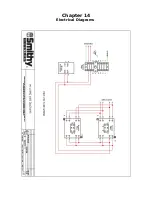

Страница 32: ...Chapter 14 Electrical Diagrams ...

Страница 33: ......