- 16 -

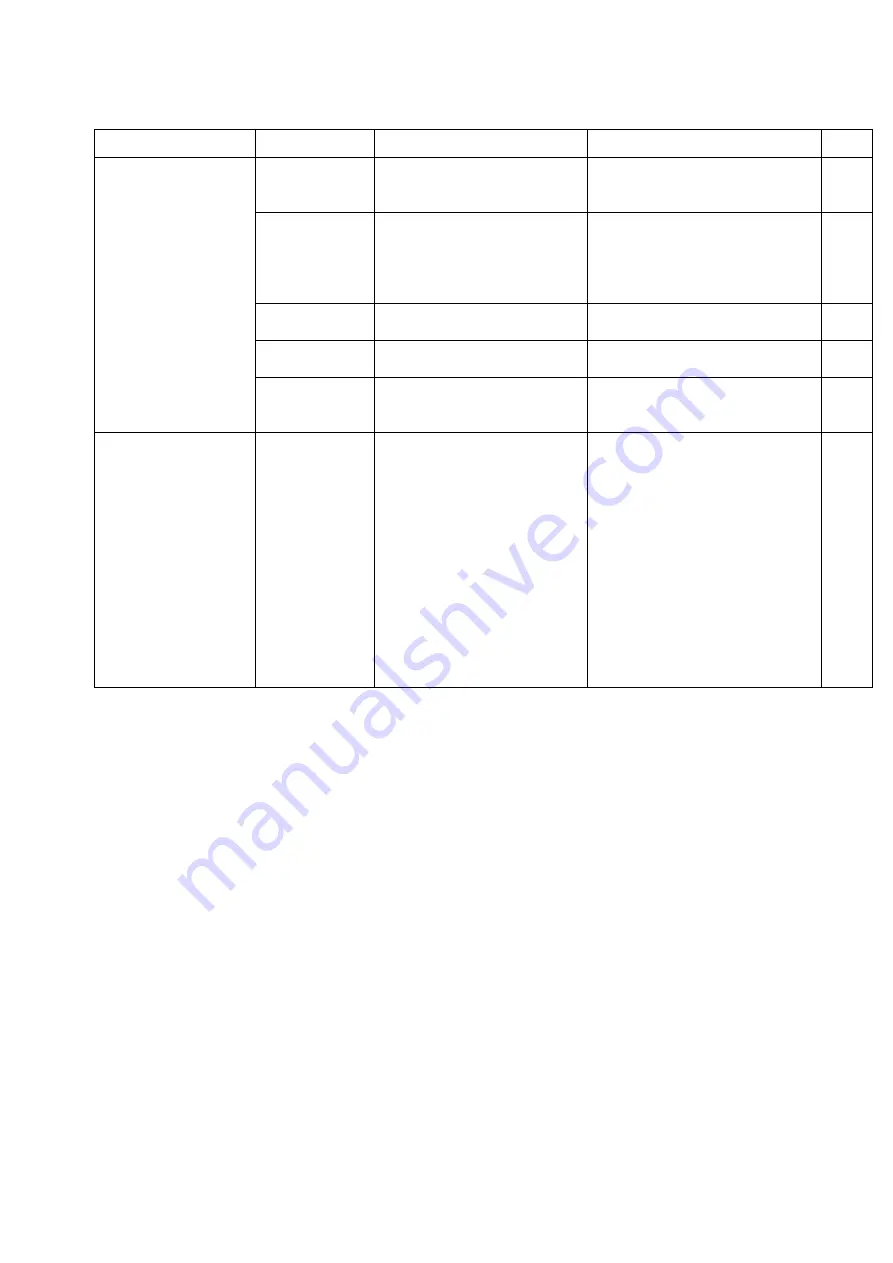

5. Troubleshooting

Trouble

Phenomenon

Possible cause

Remedy

Related

section

–The operation is

not smooth.

–The force output is

reduced.

–The cylinder

doesn’t

operate.

Air leakage

(Piston

seal

leakage)

The piston packing is worn

due to grease washed away

by water.

Install air cleaning equipment,

in the line.

2-5

2-7

A

lack

of

pneumatic

pressure

1) The pressure from the

factory source is reduced.

2) The regulator setting has

been displaced.

3) The piping is clogged.

1) Supply adequate pressure.

2) Set regulator properly.

3) Flush the piping.

1-1

2-3

Overload

The lateral load has been

exceeded.

Use within the allowable value.

1-5

Low operating

speed

The speed is lower than

specified piston speed.

Use within specifications.

1-1

Improper

pneumatic

circuit design.

The system construction

is not suitable.

Select adequate size of tube,

fitting, directional control valve,

speed controller etc.

2-2

2-3

–A part is damaged. Breakage

of

piston, tube.

1) The speed is too high due

to insufficient adjustment

of the speed controller.

2) The kinetic energy

exceeds the allowable

value.

3) The lateral load exceeds

the allowable value.

4) An abnormal external

force is applied.

1) Adjust the speed with the

speed controller again so

that

the

speed

will

decrease

within

the

specifications.

2) Use within the allowable

value.

3) Use within the allowable

value.

4) Mechanism interference,

eccentric load and overload

could cause deformation

and damage of the cylinder.

Remove these factors.

1-1

1-4

1-5

2-1

2-2

Содержание CJP Series

Страница 14: ... 13 3 Construction Description ...

Страница 16: ... 15 4 2 Accessory bracket dimensions ...