- 11 -

I.D.4mm. This nipple fits both nylon tube and urethane tube. Connection process of nylon or

urethane tube is as follows.

1) Remove the box nut, pass nylon tube or urethane tube through the nut.

2) Insert the tube into the fitting body.

3) Fasten the nut to the body.

6) When the cylinder direction is switched, select an appropriate solenoid valve for

direction control from SMC stock. 3-Port solenoid valve is used for switching the

valve.

2-4. Lubrication

Warning

1) Lubricating non-lube type cylinders

These cylinders have been lubricated for life at the factory and can be used without

any further lubrication. However, in the event that it is lubricated additionally, be sure

to use the following one. Stopping lubrication later may lead to malfunctions because

the new lubricant will cancel out the original lubricant. Therefore, lubrication must be

continued once it has been started.

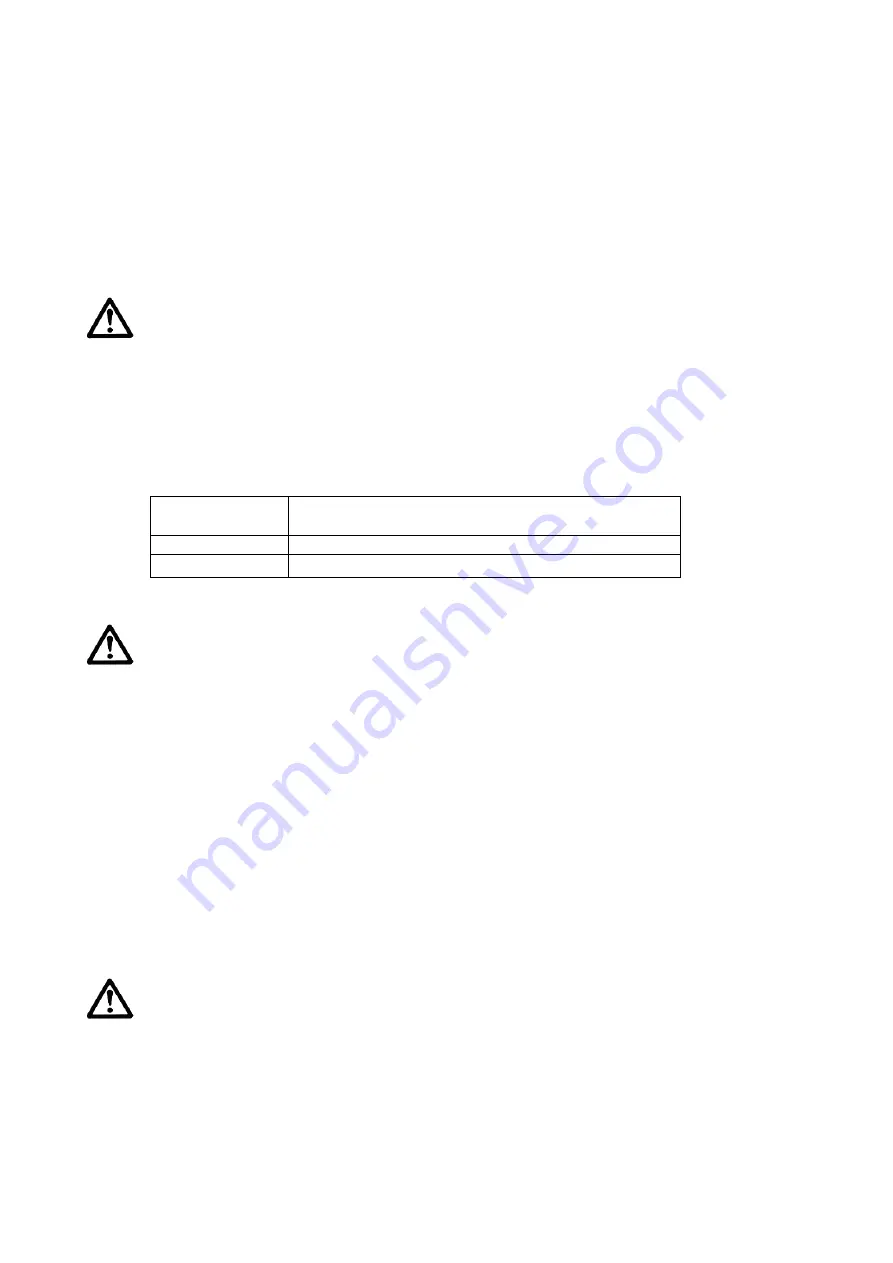

Bore size

(mm)

Kind of lubrication oil

4

Polyalphaolefin oil or equivalent oil

6

、

10

、

16

class 1 turbine oil (with no additives) ISO VG32

2-5. Air supply

Warning

1) Type of fluids

Please consult with SMC when using the product in applications other than compressed air.

2) When there is a large amount of drainage

Compressed air containing a large amount of drainage can cause the malfunction of pneumatic

equipment. An air dryer or water separator should be installed upstream from filters.

3) Drain flushing

If condensation in the drain bowl is not emptied on a regular basis, the bowl will overflow and

allow the condensation to enter the compressed air lines. This causes the malfunction of

pneumatic equipment. If the drain bowl is difficult to check and remove, the installation of a

drain bowl with an auto drain option is recommended.

For compressed air quality, refer to the SMC Best Pneumatics No. 6 catalog.

4) Use clean air.

Do not use compressed air that contains chemicals, synthetic oils that include organic

solvents, salt, corrosive gases, etc., as it can cause damage or malfunction.

Caution

1) When extremely dry air is used as the fluid, degradation of the lubrication

properties inside the equipment may occur, resulting in reduced reliability

(or reduced service life) of the equipment. Please consult with SMC.

2) Install an air filter.

Install an air filter upstream near the valve. Select an air filter with a filtration size of 5 μm

or smaller.

3) Take measures to ensure air quality, such as by installing an aftercooler, air dryer,

or water separator.

Содержание CJP Series

Страница 14: ... 13 3 Construction Description ...

Страница 16: ... 15 4 2 Accessory bracket dimensions ...