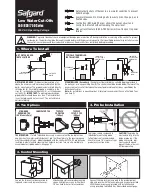

1 - FOR COMPLETE VALVE INSTALLATION, START HERE. FOR RESS RETROFIT

INSTALLATIONS, START AT STEP 6. INSTALL OPTIONAL SWEAT SOLDER ADAPTER

(ONLY IF YOUR SUPPLY PIPE DOES NOT HAVE A MALE THREAD).

3

WITH THE EXCEPTION OF CONTROL STOP INLET, DO

NOT USE PIPE SEALANT OR PLUMBING GREASE ON ANY

VALVE COMPONENT OR COUPLING!

!!! IMPORTANT !!!

PROTECT THE CHROME OR SPECIAL FINISH OF SLOAN

FLUSHOMETERS — DO NOT USE TOOTHED TOOLS TO

INSTALL OR SERVICE THESE VALVES. USE A SLOAN

A-50 SUPER-WRENCH™, SLOAN A-109 PLIER WRENCH

OR SMOOTH JAWED SPUD WRENCH TO SECURE ALL

COUPLINGS. ALSO SEE “CARE AND CLEANING” SECTION

!!! IMPORTANT !!!

THIS PRODUCT CONTAINS MECHANICAL AND/OR

ELECTRICAL COMPONENTS THAT ARE SUBJECT TO

NORMAL WEAR. THESE COMPONENTS SHOULD BE

CHECKED ON A REGULAR BASIS AND REPLACED AS

NEEDED TO MAINTAIN THE VALVE’S PERFORMANCE.

!!! IMPORTANT !!!

A

Measure from finished wall to C/L of Fixture Spud. Cut pipe 1¼” (32

mm) shorter than this measurement. Chamfer O.D. and I.D. of water

supply pipe.

WATER SUPPLY

PIPE

FINISHED WALL

1-1/4” (32

mm)

C/L OF

FIXTURE

SPUD

SWEAT

SOLDER

ADAPTER

B

Slide Threaded Adapter fully onto pipe.

C

Sweat solder the Adapter to pipe.

WITH THE EXCEPTION OF CONTROL STOP INLET, DO

NOT USE PIPE SEALANT OR PLUMBING GREASE ON ANY

VALVE COMPONENT OR COUPLING!

!!! IMPORTANT !!!

BAK-CHEK

®

CONTROL

STOP

COVER TUBE

IRON PIPE NIPPLE OR

COPPER PIPE WITH

SWEAT SOLDER ADAPTER

SET

SCREW

SUPPLY

FLANGE

WATER

SUPPLY PIPE

SWEAT

SOLDER

ADAPTER

COVER

TUBE

WALL

FLANGE

A

Measure from finished wall to first

thread of Adapter or threaded supply

pipe (dimension “X”). Cut Cover Tube to

this length.

B

Slide Cover Tube over pipe. Slide Wall

Flange over Cover Tube until against

wall.

Thread Control Stop onto pipe. Tighten

with a wrench.

C

Tighten Set Screw with a 1/16”

hex wrench. DO NOT install Vandal

Resistant Stop Cap at this time.

D

A

Open Control Stop.

C

Close Control Stop.

B

Turn on water supply to flush line of any debris or sediment.

THE STRAP WRENCH PROVIDED WITH SLOAN ECOS

®

ELECTRONIC IS A CONVENIENCE TOOL AND IS NOT TO

BE USED TO REMOVE OR INSTALL THE FLUSHOMETER

COUPLINGS. USE STRAP WRENCH ONLY TO INSTALL

SLOAN ECOS

®

ELECTRONIC LOCKING RING.

!!! IMPORTANT !!!

“X”

2 - INSTALL COVER TUBE, WALL FLANGE AND CONTROL STOP TO SUPPLY PIPE

3 - FLUSH OUT SUPPLY LINE

When further assistance is required,

please contact your local Sloan Representative

or call Sloan Technical Support at:

1-888-SLOAN-14 (1-888-756-2614)

!!! IMPORTANT !!!