15

7241

5

2022

-

ERV130 & ERV170 & ERV210

MG_0587

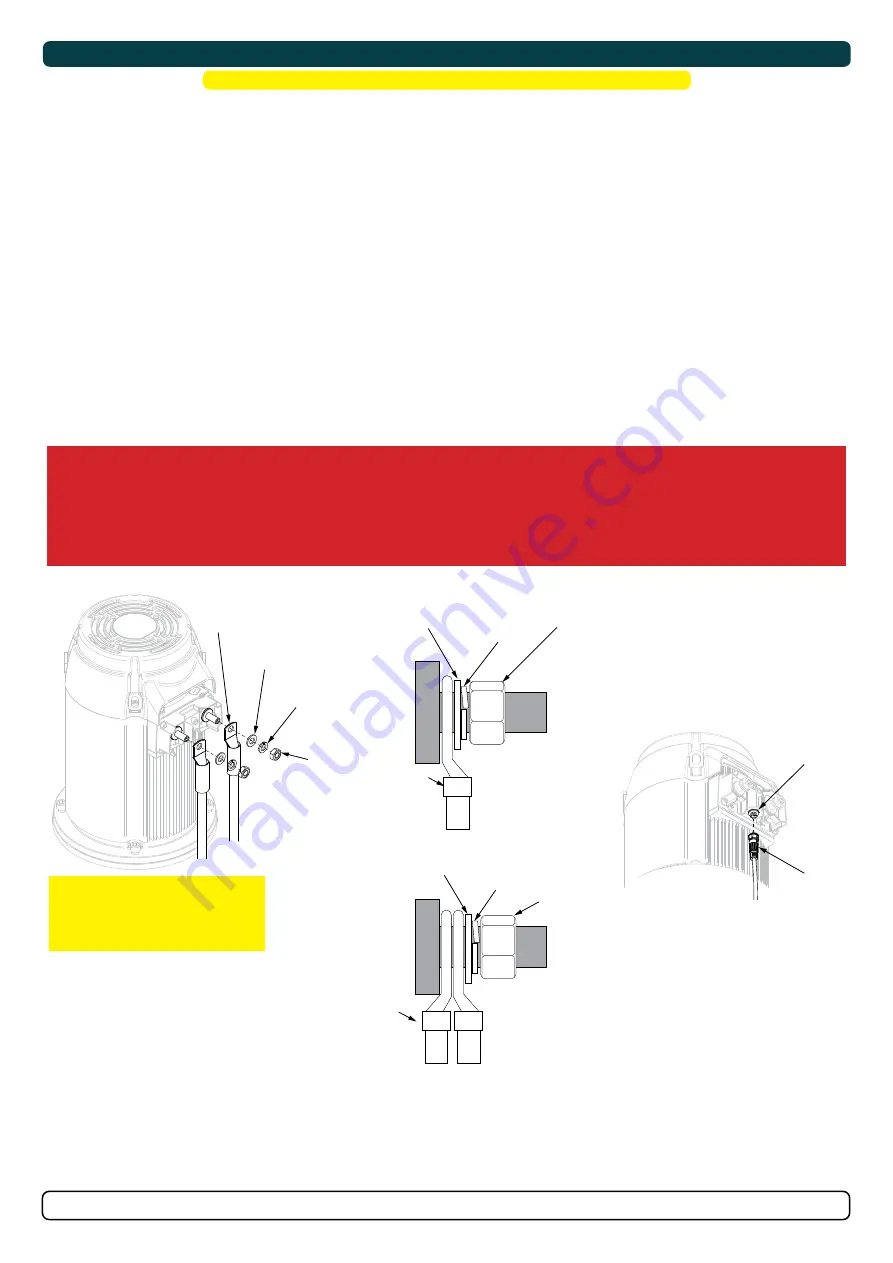

Bolt tightening force (4x)

33 Nm (24 lb/ft)

Install the relevant motor and

other electronics according to

electrical instructions in the

manual

Motor to House Installation

1. Install the motor onto the motor bracket ensuring the couplings and the drive shafts have locked together. The motor must be installed with

the solenoid facing the control box.

(NB: depending on your coupling you may need to wiggle the motor into place. Ensure the couplings are

engaging correctly. Ensure the motor cable terminals are accessible for electrical installation later.)

2. Fasten the bolts holding the motor to the motor bracket with the above torque.

3. Check the drive shafts engage by rotating the propeller. It is required the propeller can rotate via hand power.

(NB: Rotating the propellers can be

hard because of the gear reduction and the motor.)

4. Apply the gear leg and propeller with anti-fouling designed for propellers. Do not apply to the propeller drive shaft, the anodes or the end of the

gear leg facing the propellers.

(NB: The motor must be covered to avoid dust from fabrication/ maintenance operation entering the motor or the solenoids. After fabrication

maintenance operations have ceased the cover must be removed before operating the thruster.)

MC_0068

!

Please refer to the graphic for special considerations relating to your model

!

MC_0143

Electrical Installation

WARNING

Check the following with the main switch is set to off :

After all electrical connections have been completed check with an ohm meter that there is no electrical connection between

1. electro-motor flange and the positive terminal on the motor

2. electro-motor flange and the battery negative terminal on the motor

If unsure contact skilled personnel.

1. Information of electrical table.

see next page

- All power cable lengths represent the total length of the combined (+) and (-) cables.

- Battery capacity is stated as minimum cold crank capacity, (CCA).

- Use slow blow rated fuses to hold stated Amp-Draw for min. 5 minutes.

- Consider the AMP hours (Ah) for your specifi c duty cycle.

2. Use appropriate sized cables and batteries with high cranking capacity to feed the thruster. The actual voltage at the motor while running the

thruster decides the motors output RPM and thrust. Use larger cables and stronger batteries for better results.

- See electrical specifi cations for advised minimum cables and batteries (CCA).

3. Install the main switch as close to the battery as possible and ensure the main positive lead can take loads without noticeable voltage drop.

- Ensure the main switch (battery isolator) can be turned off independently and manually when not on board or in emergencies.

- Ensure it is easily accessible and update instructions that this should be turned off like the boat’s other main switches.

It is advised to install a fuse in the positive lead for protection against short-circuiting.

- Ensure a slow type and appropriately sized to take the amperage draw for at least 5 minutes.

(NB: For Ignition Protected installations remember to use ignition protected fuses and switches if fi tted in areas that require this feature.

Ensure to follow your national regulations)

5. Cable lugs must have adequate electrical and mechanical isolation and fi tted with cable lug covers.

6. Fasten cables to the required torque.

!

Please refer to the graphic for special considerations relating to your model

!

MG_0523

End nut

End nut

S-Link cable

S-Link

Connector

(M10) Nut

Tighten to *max

13 Nm (9.59 lb/ft)

Spring

washer

Spring

washer

Washer

Washer

Lugs

Lug

IMPORTANT

Do NOT use washers between lugs,

this causes overheating and fire. Spring

washers must be placed in the outer

position before tightening the nut.

Lugs

End nut

Spring

washer

Washer

Multi-lug

configuration

Ensure lug faces

are back to back.

Single-lug

configuration

Ensure lug faces

are back to back.