5

3.

Instruction for installation and setting at work

General premise:

The installation of the SINGLE LAMP sterilization units must be carried out

by specialized staff, scrupolously following the instructions hereby given. It has been moreover

considered necessary to give some general information about the electrical and water connections.

Cautions:

check that the UV panel is not connected to the power supply and that the tap of the

water to be treated is turned off.

•

Connect the delivery of the water to be treated to the special water connection

•

Turn on water and check for possible leaks in any part of the unit

•

Connect the plug to the current tap

•

Check that the disinfected water comes out and that the LEDS on the panel of the control board,

signal the correct working

Let the disinfected water flow down to outlet for at least 10 minutes before using it, in order to

make the possible impurities present in the unit drain out.

NOTE: it is recommended to install a water filter directly before the UV sterilizer in order to

remove the suspended particles, eventually present in the water to be treated, which could limit

the efficiency of sterilization.

CHECKS

The SINGLE LAMP UV System is ready for producing disinfected water, once the connection to

the water system and to the electrical grid is carried out. The unit works automatically, the

electronical boards which control the signals reaching the control panel, allow the visualization

(or the sonorization) of the correct working or of anomalies which may occur during the operating

of the unit.

MAINTENANCE

The UV System of SINGLE LAMP series have been projected and realized by S.I.T.A. Srl with

simple and functional principles which make the checking procedures and the periodical servicing

particularly easy.

The main points which characterize the ordinary servicing are the following: check quarterly the

quartz sleeves, which contain the UV lamps, in order to ensure the maximum disinfection, for the

cleaning.

Maintenance work may only be carried out by personnel who have been trained and authorized

for this work by the owner and/or user. The owner and/or user must ensure that the maintenance

personnel are familiar with the safety measures and regulations, and that they also comply with

them, in addition to having read and understood the operating instructions.

Only

original

replacement

parts

from

the

supplier

must

be

used.

The following are the recommended service intervals for replacement parts:

UV lamp change - once per 9000 hours.

UV quartz sleeve clean - frequency depends on the quality of the water.

O-ring for quartz sleeve-once per year.

Procedure for the UV lamp replacement (9000 h max.)

1) disconnect the electrical box from the electrical grid

2) lift the cover slightly turning, carefully loosen the electrical 4-pins connection, and extract the

lamp from the quartz sleeve

3) remove the lamp from the packing, handling it carefully by its ends

4) insert the new lamp into the quartz sleeve of the UV System

5) connect the lamp to the electrical connection and put again the cover

6) connect again the equipment.

N.B. for the replacement of the lamp it is not necessary to turn water off

Содержание 405 AL2

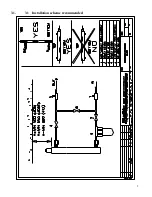

Страница 8: ...7 3 1 3 1 Installation scheme recommended ...

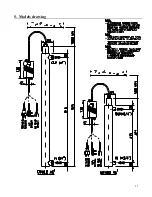

Страница 12: ...11 5 Models drawing ...

Страница 13: ...12 ...

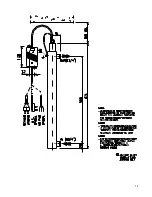

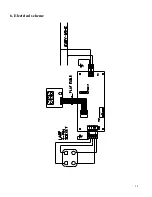

Страница 14: ...13 6 Electrical scheme ...