–remove the cover (6) of the outer

casing;

– remove the screw that fastens

each burner (7) t o the burner

ramp, sliding it out of the combu-

stion chamber;

–loosen off the screws that fasten

the upper front inner panel (4) and

remove the panel;

–r emove t he cleaning plat e (5),

unscrewing the screws that fasten

to the smoke chamber;

–using a plastic tube-brush, clean all

smoke passages and ducts;

–once the boiler body has been clea-

ned, next clean the burners, blowing

in a jet of air;

–check positioning of electrodes and

their state of wear;

–clean the connection to the chimney

and check efficiency of flue.

–after assembly of all the gas con-

nections, these must be tested for

soundness, using soapy water or

appropriate products. DO NOT USE

NAKED FLAMES.

Preventive

maintenance

and

checking of efficient operation of

equipment and safety devices must

be carried out exclusively by the

authorized engineer.

4.6

FAULT FINDING

Electric power is reaching control

panel, but boiler fails to start.

–Check that gas is reaching boiler.

–Check regulating and safety thermo-

stats are closed.

–No gas is reaching pressure switch.

– Check electronic equipment is opera-

ting properly. If necessary, replace.

Boiler keeps turning on and off, and

red warning lamp on panel keeps

going on and off.

–Check for pressure drops in the gas

suppl y sy s t em when t he boiler

starts up. The value of the dynamic

pressure at the gas valve inlet must

not be less than 9.7 mbar.

–Check the gas-line.

–Check for load losses of any solenoid

valves and safety devices installed

upstream of the gas unit.

–Check setting and operation of the

gas pressure switch; if necessary,

replace.

Discharge spark present on ignition

electrode, but burner fails to light.

– Air is present in the pipe upon first

ignition or after long periods of lay-off.

–Check whether the rectifier card on

the connector that supplies the gas

solenoid valve is working properly. If

necessary, replace.

–Valve coil has a break in the winding;

replace.

No discharge spark noted on ignition

electrode.

–Electric wire is interrupted or not

properly fastened to terminal 10.

–Equipment has transformer burnt

out; replace.

Flame detection failure.

– The positions of live and neutral on

the terminal block are not respected.

–Check whether earth wire has been

connected.

–The electrode wire is interrupted or

is not well fastened to terminal 8.

–The sensing electrode is earthed.

–The electrode is badly worn out or

the ceramic protection is damaged;

replace.

–The equipment is faulty; replace.

–With live/live electric lines, it may

be necessary to install the transfor-

mer code 6239700.

Boiler operates only at nominal pres-

sure and does not reduce pressure.

–Check whether there is voltage at

both ends of coil.

–The coil has a break in the winding;

replace.

–The rectifier card that supplies the

coil is interrupted; replace.

–There is no differential on setting of

the two contacts of the regulating

thermostat; replace.

–Check calibration of reduced pres-

sure adjusting screw (4 fig. 19) of

coil assembly.

Boiler tends to turn off easily and

forms condensate.

–Check that the flame of the main

burner is well regulated and that

gas consumption is proportional to

boiler output.

–Poor ventilation of premises where

boiler is installed.

–Flue with insufficient draught or not

meeting requirements.

–The boiler works at too low tempe-

ratures. Adjust the boiler thermo-

stat to higher temperatures.

Thermostat switches boiler back on

with too high temperature difference.

–Replace r egulating t her mos t at

since it is out of calibration.

59

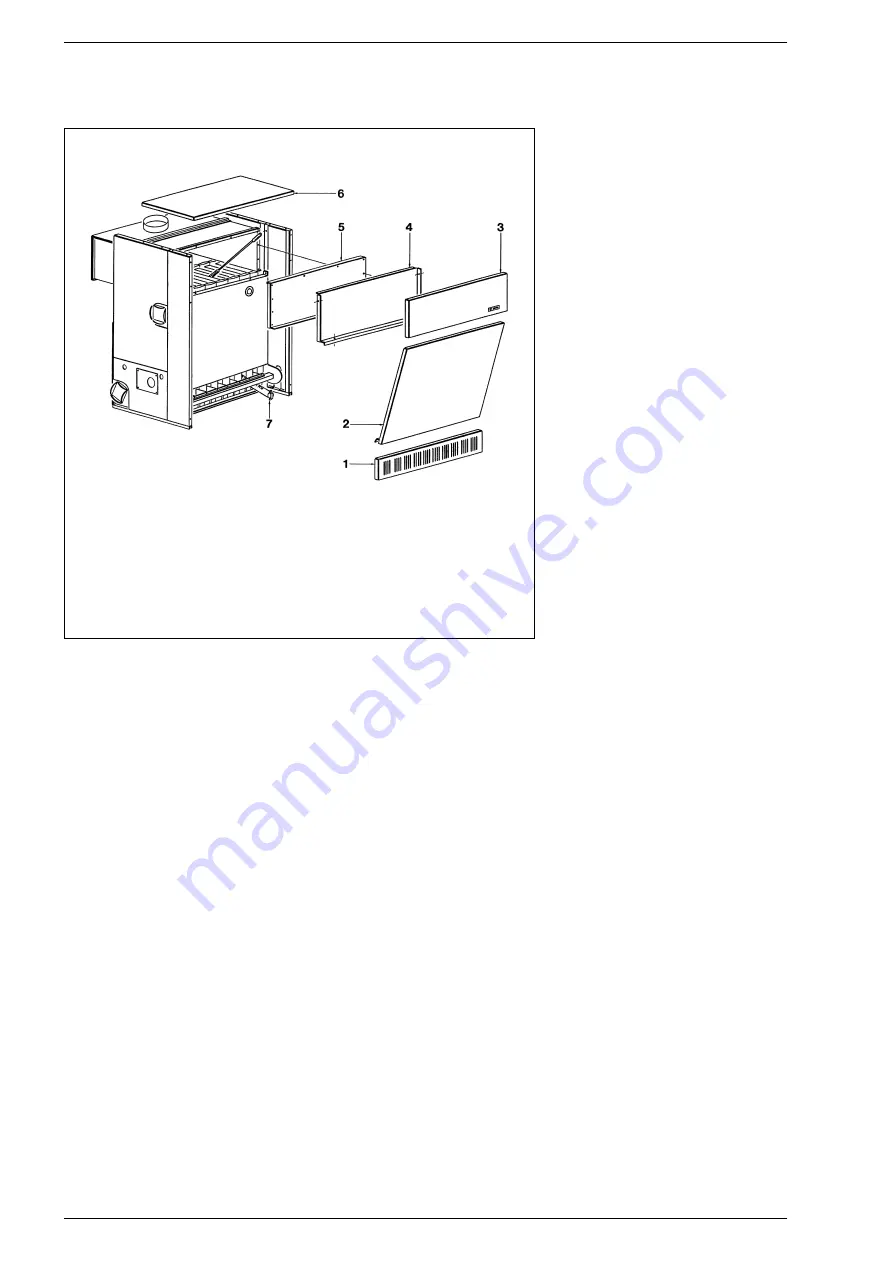

KEY

1 Casing base strip

2 Casing door

3 Upper front panel

4 Upper front wall

5 Smoke chamber

cleaning plate

6 Casing cover

7 Burner

Fig. 21

Содержание RS 10

Страница 1: ...RS IT ES GB PT...