28

–

SAFETY THERMOSTAT ERROR

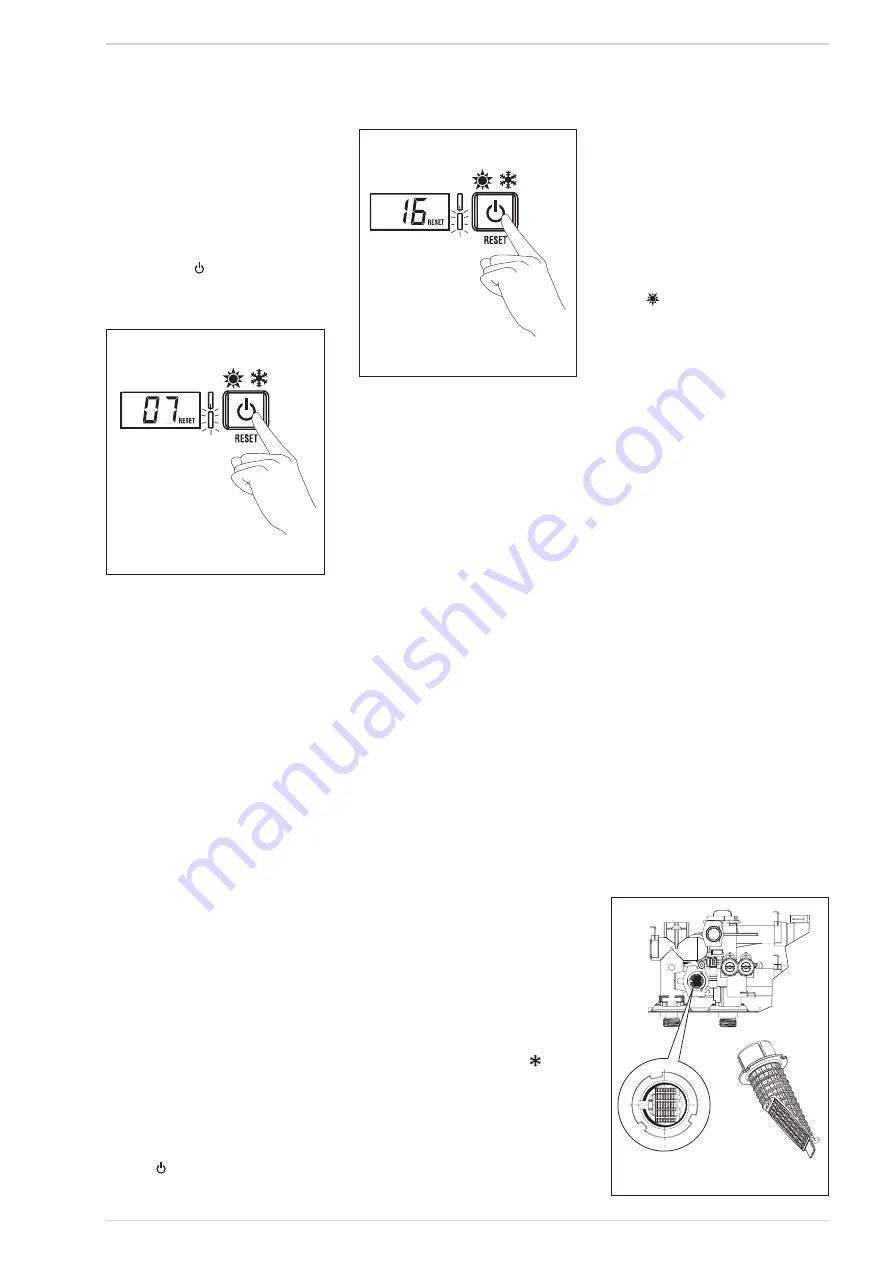

ALARM 07 (fig. 18/c)

If the C.H. sensor (SM1/SM2) exceeds

the 100°C the boiler will not ignite, the

display shows AL07 and the green LED

will stay lit. If the error persists for more

than one minute, the boiler will stop and

the red LED will illuminate.

Press the key

of the controls to start

up the boiler again.

–

FLAME DETECTION ERROR

ALARM 08

If a flame is detected when one should

not be present; the boiler will stop and

the display will show anomaly “AL 08”.

–

AUXILIARY SENSOR ERROR

ALARM 10

This error is not applicable to UK boilers,

check the setting of PAR 2.

–

MODULATOR ERROR ALARM 11

If the gas valve modulator coil becomes

disconnected or open circuit the display

will show "AL 11".

The boiler will function at minimum

power.

–

HEATING PROBE POSITIONING

ERROR SM1/SM2 “AL 16” (fig. 18/d)

If the heating probe sensor does not

detect a temperature rise within 10

seconds after a burner ignition, the bur-

ner will switch off, the display will show

AL16 and the green LED will stay lit.

If the error occurs three times within a

24hr period, the boiler will lockout, the

display continues to show AL16 and the

red LED illuminates.

Press

on the control panel to re-start

the boiler.

–

SENSOR ERROR “AL 17”

When the two sensitive elements of the

heating probe (SM1/SM2) dif fer to

each other by more than 16°C the boiler

does not operate and the display shows

error AL 17.

Replace the heating probe (SM1/SM2)

to restore operation.

4.6 COMMISSIONING

AND

ROUTINE SERVICE

Commissioning and servicing can only be

done by a qualified engineer.

4.6.1 Commissioning

PLEASE NOTE: The gas val ve f or t his

appliance has been checked, adjusted and

preset at the factory for operation on the

gas type defined on the appliance data

plate.

However it is advisable to check that the

gas valve is set correctly having first

checked:

- That the boiler has been installed in

accordance with these instructions.

- The integrity of the flue system and the

flue seals.

- The integrity of the boiler combustion cir-

cuit and all the relevant seals.

The following procedure should be done

after installation a gas purge and tight-

ness/drop test have been made.

Ensure that the auto air vent (13 fig. 3) is

opened, turn the electrical supply on.

With the boiler on standby fill the system

and pressurise to 1.5 bar (fig. 18/a).

Ensure that the pump has been manually

rotated.

Open the gas cock, press the “

mode

key” (fig. 10).

Check the operational (working) gas inlet

pressure.

Set up the boiler to operate at maximum

r at e as descr ibed in 4.4.1 (Chimney

sweep]).

With the boiler operating in the maximum

rate condition check that the operational

(working) gas pressure at the inlet test

point (see fig 14 item 3) is 21 mb +/- 2

mb.

Ensure that this inlet pressure can be

obtained with all other gas appliances in

the property working.

Check the setting of the gas valve, using

the procedure described in 4.2.2.and com-

pare the values to those shown in table 3.

Press “

mode key” (fig. 10).

Turn on a DHW tap fully (preferably the

bath tap), ensure that the boiler ignites.

Set the controls to the required values as

shown in the user guide.

Complete the Benchmark sheet enclosed

in this manual.

Explain controls and operation to the user.

Leave all documentation with the user.

Ensure that the boiler is registered with

gas Safe Register and Sime Ltd within 30

days of installation, and request that the

owner records the registration number in

the Benchmark checklist.

4.7

ROUTINE SERVICE

To comply with the conditions of any exten-

ded warranty offered and to ensure conti-

nued safe and efficient operation, the boiler

must be serviced at regular intervals at

least once a year.

It is the law that a Gas Safe Register regi-

stered engineer, must carry out any service

work.

4.7.1

Check / Clean Filter (fig. 19)

The filter is located within the connection of

the heat exchanger outlet pipe and the

DHW hydraulic assembly. Fig 19.

To check or clean the filter, turn off the gas

and electrical supplies to the boiler.

Close the flow and return isolation valves

and drain the boiler.

Protect the internal components of the boi-

ler fro accidental water spillage, then

Fig. 18/c

Fig. 18/d

Fig. 19

Содержание ECOMFORT PLUS 25 HE

Страница 3: ......

Страница 44: ...44 NOTES ...

Страница 45: ...45 NOTES ...

Страница 46: ...46 NOTES ...