.

A long nylon control horn is supplied for the elevator. Install it on the bottom of the left elevator with #2x3/4" sheet metal

screws. Once installed, cut off the excess ends of the screws flush with the top of the nylon retainer plate.

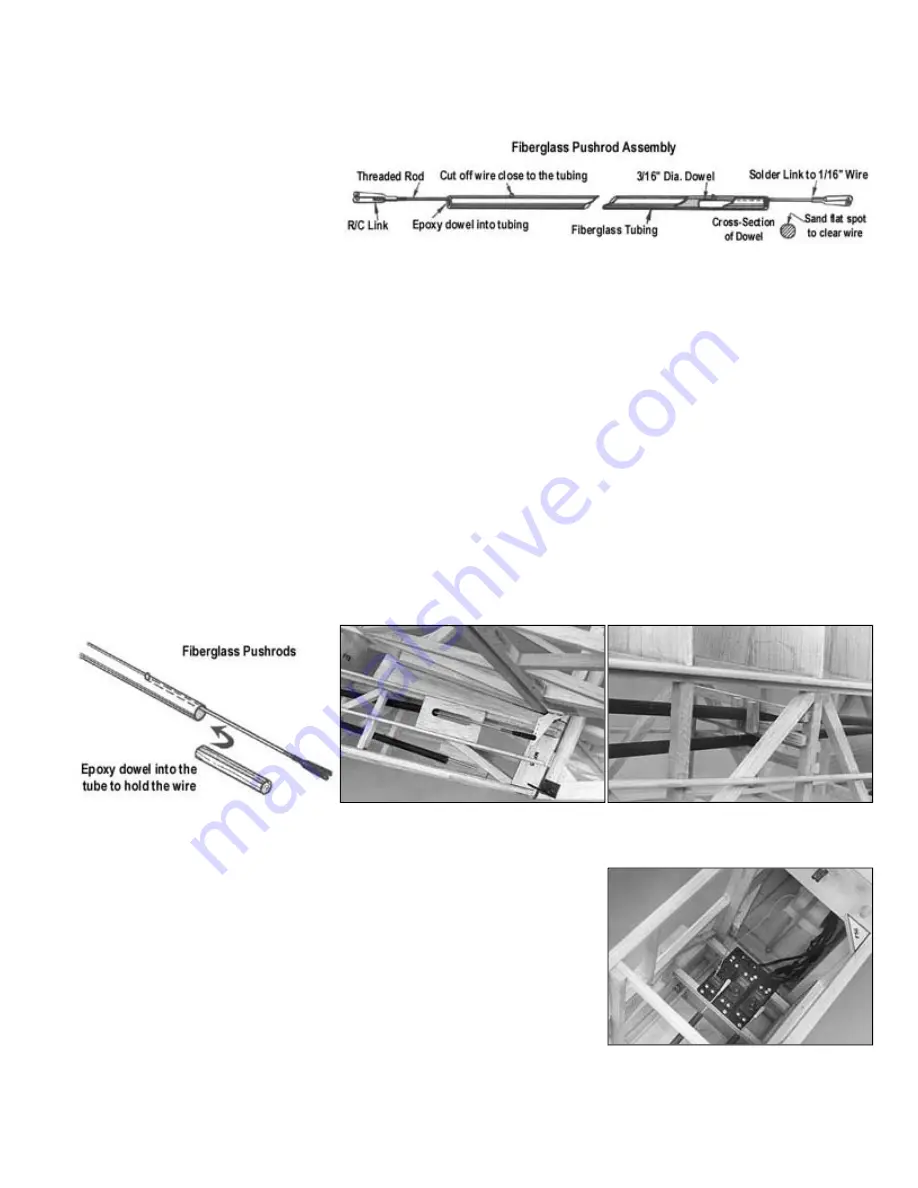

Pushrod Assembly

Materials are supplied for building

fiberglass pushrods to link the elevator

and rudder servos to their control horns.

Make the control surface ends of the

pushrods first.

Put a 90° bend in the unthreaded end of the 4-40x8" threaded rod. Drill a 3/32" diameter hole 2" from the end of the

fiberglass pushrod tube. Slide the 4-40 rod into the tube, sticking the 90° bend through the hole.

Sand a flat spot on one side of the 3/16"x2-1/2" dowel until it can be squeezed into the tube alongside the 4-40 rod. When

you get the fit right, final assemble the parts into the tubes with epoxy glue. It should not be necessary to put any bends in

the 4-40 wires of either the elevator or rudder pushrod to get them to feed through the fuselage and hook up to the control

horns. It's a pretty straight shot if your servos are positioned side by side as shown in a previous photo. However you may

have to trim out a portion of the diagonal 5/16" sq. main frame balsa under the stab to clear the elevator pushrod wire.

Assemble the servo ends of both pushrods in the same fashion, only use 1/16" dia. x 8" music wire and solder links instead

of the 4-40 size hardware. After you've got the 1/16" wires and dowels epoxied into the tubes, feed the pushrods back into

the fuselage and hook up to the control surfaces. Center the 4-40 links on the threads at the tail end. Then measure and

cut off the 1/16" wires at the front, to the length which will allow the solder links to reach the servo arms. Protect the servos

with a rag while soldering the links onto the ends of the wires.

Your elevator and rudder pushrods should now be complete and operating freely. Fill in around the 4-40 pushrod wires

where they exit the fuselage with scrap sheet balsa, glued in flush with the stringers.

Brace the pushrods in the middle (near former F9) with 1/4" sq. scrap balsa to eliminate any possibility of in-flight vibration

or bowing problems. Criss-cross pieces of 1/4" sq. stick on all four sides of each push rod. Glue them to the 5/16" sq. main

frame balsa. Have the braces touching the pushrods, but not creating a bind.

Throttle Hookup

Either a standard or heavy-duty servo can be used for the throttle control on a .60

to .90 glow engine. A flexible steel cable pushrod with nylon outer tubing (*, such

as SIGSH559) is best for hookup of the throttle servo to the carburetor. Follow the

assembly instructions on the pushrod package.

Battery Pack

Due to the larger than normal battery drain from using heavy-duty servos, a 1000

mah receiver battery pack (*) is recommended. Wrap the battery pack in foam

rubber (*, such as SIGRF240) held on with rubber bands or masking tape, to

protect it from engine vibration. Secure it as far forward as possible in the nose

under the fuel tank.