815_58300000003806_ara_en_e.doc – 30.01.12

Seite 30 von 67

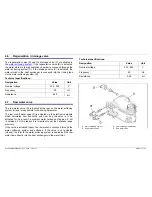

4.20 Water inlet with heat exchanger

When the filling valve has been opened, the water flows towards the

integrated inlet via the free flow channel and into the water softening

system and as soft water into the heat exchanger. When the

regeneration chamber has filled up, the water flows into the restricting

funnel of the level sensor via the overflow channel. The pressure

build-up in the pressure chamber causes the level switch to open the

heat exchanger drainage valve. The electronics measure the time

between the opening command of the filling valve and the closing of

the level switch (f1). The additional filling time of the filling valve is

calculated from this time.

The circulation pump is switched on time-delayed, the drainage valve

remains open until the heat exchanger has emptied completely.

The water volume of completed rinse cycles is recorded by the

electronics counter which determines when the water softener

requires regeneration.

Before each regeneration step the electronics check whether the

capacity of the water softener is adequate for a complete "Normal

Programme Sequence". If not, regeneration starts.

The water softening system is regenerated and rinsed through during

the wash cycle. The regeneration valve on the water softening system

is opened for this purpose. The stored volume of water flows into the

salt dispenser via the valve, absorbs salt and flows as saline solution

through the water softening system into the heat exchanger. Rinsing

takes place in three stages, each with one calculated volume of water.

A Free flow line

J Float in the base pan

B Leakage

water

K Salt

dispenser

C Overflow

channel

L Ion

exchanger

D Heat exchanger

M Heat exchanger drainage valve

E Pressure switch, level f1

N Regeneration valve

F Switch

lever

O Water

inlet

G Safety pressure switch

P Regeneration chamber

H Air chamber level

Q Drainage hose ventilation valve

I To the pump sump