OpenAir™ GCA Series Spring Return 160 lb-in Electronic Damper Actuator

Technical Instructions

Document No. 155-173P25

May 19, 2014

Siemens Industry, Inc.

Page 11

Sizing

The type of actuator required depends on several factors.

1. Obtain damper torque ratings (ft-lb/ft

2

or Nm/m

2

) from the damper

manufacturer.

2. Determine the area of the damper.

3. Calculate the total torque required to move the damper:

Total Torque =

SF

Area

Damper

Rating

Torque

1

×

1

Safety Factor: When calculating the total torque required, a safety factor

should be included for unaccountable variables such as slight misalignments,

aging of the damper, etc. A suggested safety factor is 0.80.

4. Select the actuator type using Table 2.

NOTE:

Mechanically coupled actuators must all be of the exact same type

except for the dual auxiliary switches and feedback potentiometer

options. Make sure to use the correct tandem-mounting bracket. See

Table 2.

Table 2.

Sizing

Total Torque

Actuator

<62 lb-in (7 Nm)

GMA

>62 lb-in <160 lb-in

(>7 Nm <18 Nm)

GCA

>160 lb-in <320 lb-in

(>18 Nm <36 Nm)

ASK73.2U*

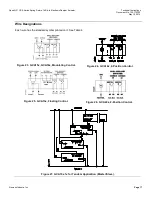

: Tandem mounting bracket with any

combination of two GCA16x (standard 0 to 10 Vdc

modulating control) actuators mounted on the same

side of the damper shaft.

ASK73.1*:

Tandem mounting bracket for two GCA 2-

position and floating control actuators that are mounted

on the same side of the damper shaft.

NOTE:

For applications requiring single damper

shaft operation by up to four GCA

modulating control signal actuators

mounted on each side of the damper shaft,

use the GCA15x Series Actuator with

Master/Slave mode operation selected. See

Figure 22 for master/slave DIP switch

settings, and Figure 27 for wiring of this

configuration.

*Tandem application tested for up to four actuators. Each bracket mounts two actuators.