•

Connect the device to the permissible supply voltage only,

•

Protect the device with a separate fuse of 0.8 A (slow blowing) at the start of

the supply circuit.

•

All circuits connected to the device must be designed as ES1 circuits. The

voltage supply or power supply unit must satisfy ES1 requirements in accor‐

dance with the currently applicable EN 62368-1.

WARNING

Risk of injury and damage caused by electrical current!

The device is designed for operation in a system with proficient ground‐

ing of all connected devices and mounting surfaces to the same ground

potential. Due to equipotential bonding currents between the device and

other grounded devices in the system, incorrect grounding of the

device can charge the metal housing to a dangerous voltage, cause mal‐

function and destruction of devices as well as damage to the cable

shielding through heating, and thus cause cable fires.

•

Ensure that the ground potential is the same at all grounding

points.

•

If the cable insulation is damaged, disconnect the voltage supply

immediately and have the damage repaired.

NOTICE

Risk of damage to the device due to possible short-circuit!

The supply voltage input for the device is designed with internal circuit

protection to provide reverse polarity protection. The internal functional

earth, which also corresponds to the negative pole of the supply voltage

for the device, is connected directly to the metal housing of the device

due to reasons relating to high frequency.

If the supply voltage is polarity-reversed, this will not cause any damage

provided that the following conditions are met for the device:

The device is not connected in an electrically conductive manner, either

via other cables or via its housing, to other peripheral devices which use

the same reference potential.

5.1 Connecting the device electrically

NOTE

The USB interface of the device is used in industrial environments only as a

service interface for temporary use (e.g. for configuration, troubleshooting).

Permanent use in real operation of the system as a host interface is not

intended.

Voltage supply

There are two ways to supply the device with voltage, as follows:

1.

Power and Ethernet: DC 18 V ... 30 V

°

Port 1: Power (24 V)

°

Port 2: Ethernet

2.

Power over Ethernet (PoE): DC 48 V / 57 V As per PoE technology

°

Port 1: Not assigned

°

Port 2: PoE

NOTE

The voltage supply via a power supply unit must be capable of bridging a

brief power failure of 20 ms.

It is possible to connect both variants at the same time; however, it is recom‐

mended to select just one variant.

Connecting connection variants at the same time

Initial situation

Adjustment

Effect

Voltage supply power via port

1

PoE via port 2 also con‐

nected.

No effect on the device sta‐

tus.

Voltage supply PoE via port 2

Power via port 1 also con‐

nected.

No effect on the device sta‐

tus.

Voltage supply with immedi‐

ate effect via power via port 1

(dominant).

Voltage supply power via port

1 (dominant) and PoE via port

2

Power via port 1 connection

is isolated.

Device restarts.

Voltage supply with immedi‐

ate effect via PoE via port 2.

After successful initialization, the

Ready

LED illuminates green.

Trigger

Read and write commands for the device can be started and ended using a trig‐

ger sensor. Trigger sensors can be connected directly to the device (port 3). The

permanently active supply voltage is received by the trigger sensor from the

device. Cover the male connectors with protective caps or male connectors when

port 3 is not in use. For additional information,

Port 3: Trigger

Figure 4: Female connector, 4-pin, A-coded

Pin assignment of the “Trigger” connection

Pin

Signal

Function

1

V

Trigger

Trigger supply voltage

Pin

Signal

Function

2

NC

NC

3

GND

Ground

4

Sensor 1

Digital input

5.1.1

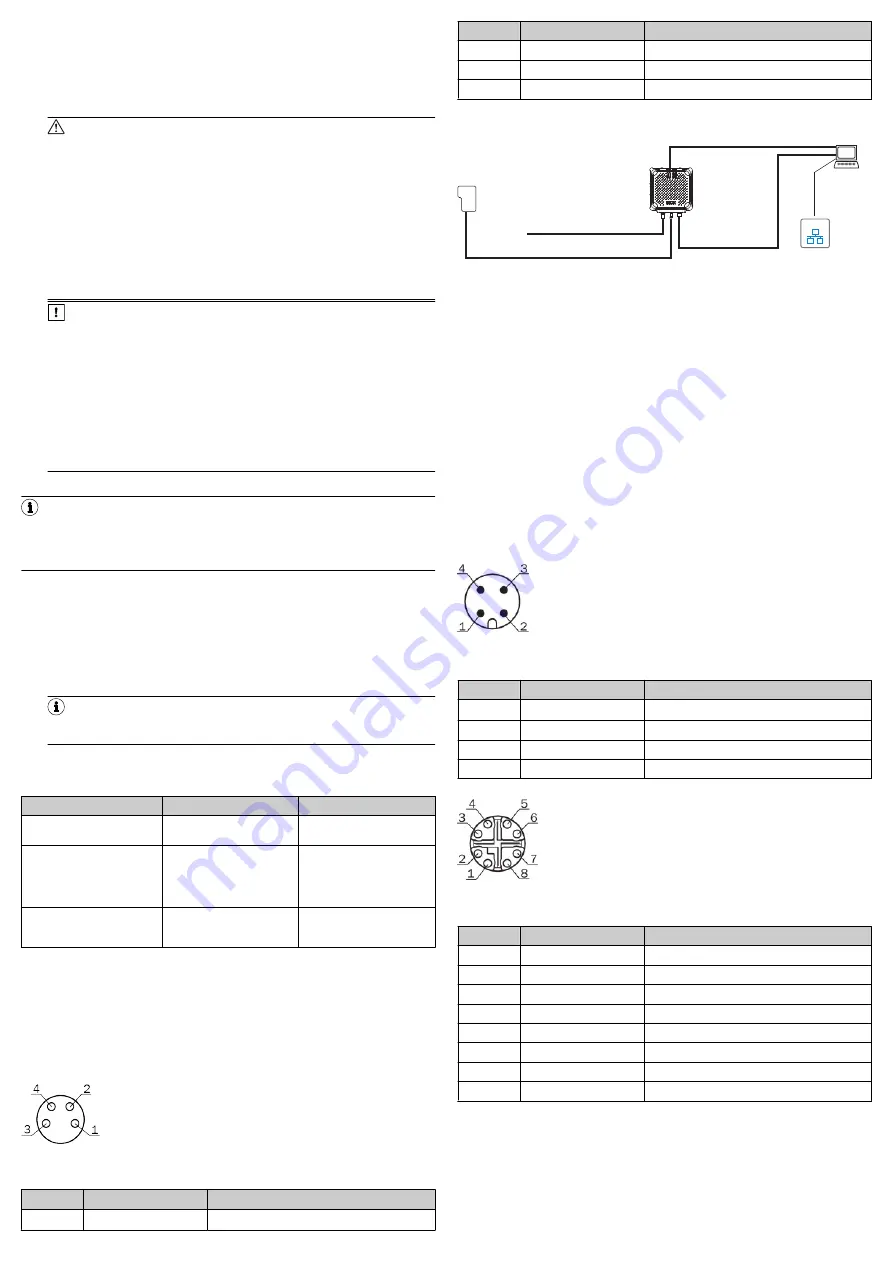

RFU610-106xx: Power and Ethernet

Configuration

Diagnostics

Transponder

access

Reading result

SOPAS ET

SOPAS ET

PC

Ethernet

Ethernet

RFU610-106xx

"Ethernet" (Host/Aux1)

Cable

6

Cable

4

Cable

5

3

Trigger

sensor

1

"Power"

“USB“

7

(Aux 2)

2

Figure 5: Commissioning: Electrical connection block diagram of the

RFU610-106xx

1

Trigger sensor (read cycle)

2

Supply voltage V

S

3

Configuration, diagnosis, transponder access or display of read

results

4

Power adapter cable (female connector, M12, 4-pin, A-coded/open

ends)

5

Ethernet adapter cable (male connector, M12, 8-pin, X-coded/male

connector, RJ-45, 8-pin)

6

Trigger adapter cable (male connector, M8, 4-pin, A-coded/female

connector, M8, 4-pin, A-coded)

7

Adapter cable (male connector, 5-pin, USB, Micro-B type/male con‐

nector, 4-pin, USB, type A)

1.

Connect port 1 directly to a supply voltage via a power adapter cable (e.g.,

2095607).

2.

Connect port 2 directly to a PC via an Ethernet adapter cable (e.g.,

6049728).

3.

Connect the trigger sensor (e.g., GL6 (1059241)) directly to port 3 of the

device via a trigger adapter cable (e.g., 2096347).

Port 1: Power

Figure 6: Male connector, M12, 4-pin, A-coded

Pin assignment of the “Power” connection (M12)

Pin

Signal

Function

1

V

S

Supply voltage

2

NC

NC

3

GND

Ground

4

NC

NC

Port 2: Ethernet

Figure 7: Female connector, M12, 8-pin, X-coded

Pin assignment of the “Ethernet” connection

Pin

Signal

Function

1

TD+

2

TD-

Sender-

3

RD+

R

4

RD-

Receiver-

5

PoE-

Supply voltage-

6

PoE-

Supply voltage-

7

PoE+

Supply

8

PoE+

Supply

8023832//2019-04-15/en

RFU610 | SICK

3