14

4 Connecting to power supply

LFV200 • IO-Link

41222-01-170809

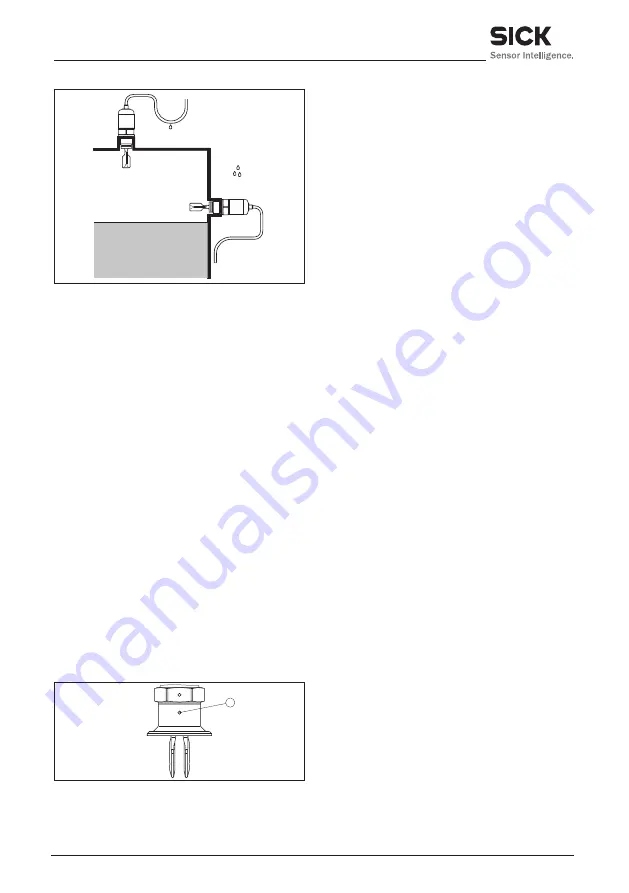

Moisture

Abb. 29: Measures against moisture ingress

Handling

Do not hold LFV200 on the tuning fork. Bending

the vibrating element will destroy the instrument.

3.2 Mounting instructions

Welded socket

For threaded versions of LFV200 in combination

with a mounting boss with O-ring in front and

welding marking.

LFV200 with thread sizes ¾" and 1" have a

defined thread. This means that every LFV200

is in the same position after being screwed in.

Remove therefore the supplied flat seal from the

thread of LFV200. This flat seal is not required

when using a welded socket with front-flush

seal.

Before welding, unscrew LFV200 and remove

the rubber ring from the welded socket.

The welded socket is provided with a marking

(notch). For horizontal mounting, weld the so-

cket with the notch facing upward or downward;

in pipelines (DN 25 to DN 50) aligned with the

direction of flow.

1

Abb. 30: Marking on the welded socket

1 Marking

Adhesive products

In case of horizontal mounting in adhesive and

viscous products, the surfaces of the tuning fork

should be vertical. The position of the tuning

fork is indicated by a marking on the hexagon of

LFV200. With this, you can check the position of

the tuning fork when mounting it.

In case of horizontal mounting in adhesive

and viscous products, the tuning fork should

protrude into the vessel to avoid buildup on the

tuning fork.

Product flow

To make sure the tuning fork of LFV200 gene-

rates as little resistance as possible to product

flow, mount the sensor so that the surfaces are

parallel to the product movement.

4 Connecting to power

supply

4.1 Preparing the connection

Note safety instructions

Always keep in mind the following safety inst-

ructions:

•

Connect only in the complete absence of

line voltage

4.2 Wiring plan

For connection to binary inputs of a PLC.

The M12 x 1 plug connection requires a ready-

made cable with plug.

For power supply, use an energy-limited circuit

according to EN 61010, paragraph 9.3.

Содержание LFV 200

Страница 39: ...39 Notes LFV200 IO Link 41222 01 170809...