5

SETTING OF FUNCTIONS

50

S

E

TTI

N

G OF

FUN

C

TIO

N

S

Chapter

5

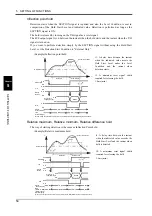

Caution regarding inflection point hold

If the detection Inflection front sope time and Inflection

rear sope time are set too short, fine load changes may be

detected as shown in the illustration on the left-hand side,

so that a correct value cannot be held.

In this case, set the detection inflection rear sope time

large enough to bring it as close to the load change time as

possible, and also set the inflection minimum slope large

according to the amount of change at that time, so that the

inflection point is held at a correct position.

Example of inflection point hold setting

●

Example of ideal waveform setting

①

Set the load change time (between the inflection point and when the change stops) to

inflection rear sope time. In the example, it is set to 200 since it is 100 msec.

②

Set the same value as inflection rear sope time to inflection front sope time.

③

Set load D obtained by subtracting load C changing with inflection front sope time from the

load changing with inflection rear sope time to the inflection minimum slope.

In the example, set load change D=80 obtained by subtracting load C=10 changing with A

from load 90 changing with B to the inflection minimum slope.

However, since an inflection point is not judged until load change D exceeds the inflection

minimum slope, actually set the inflection minimum slope a slightly smaller than D.

●

If the inflection point cannot be located successfully

①

When holding above the inflection point and moving downward

1) It is considered that the inflection minimum slope is small with

respect to load change D. Set the inflection minimum slope

larger.

2) If lowering is insufficient in 1), increase inflection front sope

time.

②

When holding below the inflection point and moving upward

inflection rear sope time is too long and the inflection minimum

slope is too large.Shorten inflection rear sope time and decrease

the inflection minimum slope.

Inflection front (rear) slope time setting is the number of samplings. Since the DS-6200's

sampling speed is 2000 times/sec., one sampling is 0.5msec.

Therefore, setting of the interval at 100 means setting of 50msec.

Load change time

True inflection

Inflection

point

point

100

20

10

0

100msec

A

100msec

B

D = 80

C = 10

①

②

Содержание DS-6200

Страница 1: ......

Страница 11: ...CONTENTS 10 M E M O...

Страница 12: ...11 11 STANDARD...

Страница 13: ...12 12 M E M O...

Страница 92: ...91 91 EXPANSION...

Страница 93: ...92 92 M E M O...

Страница 95: ...Expansion Function 94 M E M O...