20

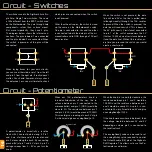

Switches

The switches will fit into their holes quite

tightly. If they don’t pop in flat to the PCB,

check that the legs are all aligned properly.

They should hold on their own, so flip the

board and solder the pins to the pads.

The pins are short so they shouldn’t need

trimming.

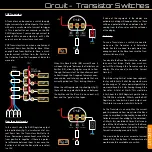

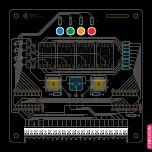

PNP Transistors

The transistors can be tricky to solder be-

cause the legs are so close together. We

have spaced the pads out a little to make it

easier. Notice the semi-circular shape of the

transistor looking at the top. Match this with

the footprint on the PCB.

The outer legs of the transistor will spread

out a little as you insert it into the holes.

Don’t push it too far as the legs will spread

too much and crack the black casing of the

transistor. Stop when there’s a 2-3mm gap.

Add sticky tack to hold in place, flip, solder,

snip and re-flow.

If you accidentally bridge two pads togeth-

er, clean your iron, re-tin the tip, then drag

the tip through the gap between the pads.

This should separate them. If it doesn’t, re-

peat the process. If your tip isn’t clean, the

solder won’t stick to the tip when you drag

it through, so make sure that tip is clean

and re-tinned.

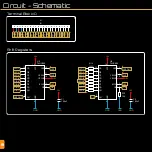

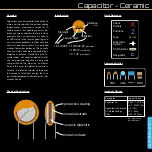

DIP16 Socket / 595 Shift Registers

We are going to solder a socket to the PCB

rather than the chip itself. We do this to

avoid heating up the IC and to enable us to

swap it out if it stops working.

Insert the sockets into the areas marked

U1 and U2. Pay attention to the semi-circle

indicator and match the one on the socket

with the one on the board.

Note: an error on v1 of the board means the semi-circles

have accidentally been omitted. Take note that the pad for

pin 1 of the IC is square. The semi-circle should be at the

same end as the square pad.

Now, stick it in place with sticky tack and

solder 1 corner pin, then the diagonally

opposite corner. Now check alignment

and whether its flush with the board. If one

corner is too high, add pressure to it while

heating the pin underneath.

Now you can solder all the other pins know-

ing that the socket will stay exactly where it

needs to be. Remove the sticky tack before

soldering the rest of the pins. As with the

Transistors, if you accidentally bridge two

of the pins, wipe your clean iron tip through

the center of them until they are separated.

DO NOT INSERT THE CHIPS UNTIL YOU

HAVE COMPLETED THE TESTING FOR

FAULTS SECTION!!!!

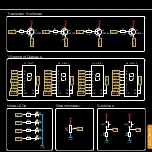

Potentiometer

Insert the legs of the Potentiometer into RV1

on the board. Hold the potentiometer with

some sticky tack and align the blue case

with the footprint. Flip the board and solder

the three pins. Snip and re-flow.

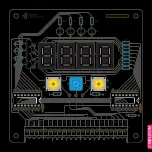

7-Segment Displays

Be aware of the orientation of the display

when inserting them into the PCB. Make

sure the decimal point is in the bottom right

corner. You can insert all 4, secure them

then solder the pins. Try not to hold the

iron on too long, as the white plastic cas-

ing can melt. You will need to snip the legs

off these as they are quite long and pokey.

Make sure you re-flow the solder joints after

you snip the legs to make sure the solder

hasn’t cracked.

RV1

Potentiometer

U1-4

7-Segment Displays

Assembly Instructions

SW1, SW2

Q1-4

U5-6

DIP16 Socket

U5-6

74HC595

2N3906

2N

3906

331

2N

3906

331

2N

3906

331

2N

3906

331