10

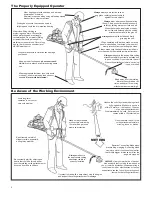

Installing Trimmer Head

To install a trimmer head

1. Position the brushcutter with the head

of the shaft bolt facing up.

2. Remove the shaft bolt, bolt guard,

Holder B and the retainer clip(s) from

the output shaft.

IMPORTANT!

The shaft bolt, bolt guard, and retainer

clips are not used with a trimmer head

cutting attachment. Save these parts for

future blade installation.

Holder B

Holder A

Gearcase Shaft

3. Re-install Holder B on the output shaft.

4. Rotate the holder until the hole in the

holder aligns with the notch on the

gearcase flange. Using the hex wrench,

lock the gearcase as shown.

5. While holding the holder with the hex

wrench, thread the trimmer head onto

the gear-shaft and install securely using

hand pressure. Turn counterclockwise

to install.

6. Remove the hex wrench.

The brushcutter can now be used as a

grass trimmer

Hex Wrench

Filling The Fuel Tank

1. Place the unit on a flat, level surface,

and wipe any debris from around the

fuel cap.

2. Remove the fuel cap.

3. Fill the tank with clean, fresh fuel.

4. Replace the cap, and wipe away any

spilled fuel before starting the engine.

IMPORTANT!

Mix only enough fuel for your immediate

needs! If fuel must be stored longer

than 30-days, it should first be treated

with a stabilizer such as STA-BIL™ or

equivalent product!

CAUTION!

Never attempt to mix fuel in the unit’s

fuel tank. Always mix all fuels in a

clean approved container.

Use only fresh, clean unleaded gasoline

with a pump octane rating of 87 or

higher.

Mixing fuel with a Premium 2-cycle

mixing oil designed for use with high-

performance 2-cycle air-cooled engines.

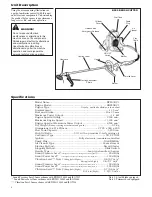

Refer to the following examples of 50:1

fuel to oil mix quantities:

Gasoline 2-cycle mixing oil

liters

milliliters

2.5 l ............................. 50 ml

5 l ................................100 ml

10 l ..............................200 ml

20 l ..............................400 ml

Mixing Fuel

WARNING!

Minimize the risk of fire,

burns, and personal injury!

STOP

engine before refueling.

ALWAYS

allow the engine to cool

before refueling

ALWAYS

open the fuel cap slowly

to allow any pressure build-up

in the tank to release fuel vapor

slowly.

ALWAYS

transport and store fuels

in an approved container.

Avoid overfilling and wipe-up all

spilled fuel. Move the engine at

least 3 meters from the fueling

point, storage area, and other

readily flammable materials before

restarting.

ALWAYS

inspect the unit for fuel

leaks before each use. During

each refill, make sure there are no

fuel leaks around the fuel cap and/

or tank. If a fuel leak is evident,

stop using the unit immediately.

Fuel leaks must be repaired before

using the unit.

NEVER

smoke or light any fires

near the engine or fuel source.

NEVER

place any flammable ma-

terial near the engine or muffler.

NEVER

operate the engine without

the muffler in good working condi-

tion.

ALWAYS

move the unit to a place

well away from a fuel storage area

or other readily flammable materi-

als before starting the engine.

CAUTION!

Some gasolines contain alcohol as

an oxygenate! Oxygenated fuels may

cause increased operating tem-

peratures. Under certain conditions,

alcohol-based fuels may also reduce

the lubricating qualities of some mixing

oils. Never use any fuel containing

more than 10% alcohol by volume!

Generic oils and some outboard motor

oils may not be intended for use in

high-performance air cooled 2-cycle

engines, and should never be used in

your Shindaiwa engine!

CAUTION!

This engine is designed to operate on

a 50:1 mixture consisting of unleaded

gasoline and a premium 2-cycle mixing

oil only. Use of Non-approved mixing

oils can lead to excessive maintenance

costs and/or engine damage.