14

VC-G20SM/G200SM

VC-G201SM/G401SM

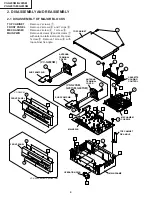

Figure 4-11.

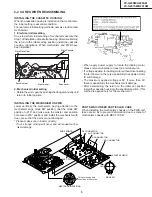

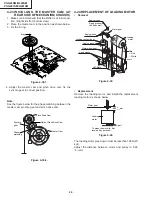

4-12 CHECKING AND ADJUSTMENT OF

TENSION POLE POSITION

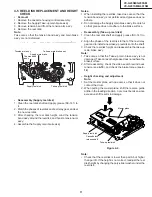

4-10 CHECKING THE VIDEO SEARCH REWIND

BACK TENSION

• Remove the cassette housing control assembly.

• After short-circuiting between TP803 and TP802

provided at main PWB, plug in the power cord.

• Checking

1. After pressing the play button, press the rewind button,

and set the video search rewind mode.

2. Place the torque gauge on the take-up reel disk, and turn

it counterclockwise very slowly (one rotation every 2 to

3 seconds) and check that the torque is within the set

value 3.7 ± 1.5mN

⋅

m (38 ± 15gf

⋅

cm).

Pinch roller

Tension gauge

900 - 1,200gf

Capstan shaft

Tension gauge adapter

Figure 4-10.

Torque gauge

Take-up reel disk

Notes:

Set the torque gauge securely on the take-up reel disk.

If it is not secure, the measurement will be incorrect.

4-11 CHECKING THE PINCH ROLLER

PRESSURE

CCW

Figure 4-12.

500g

Weight to prevent

float (500g)

(E-180)

•

Remove the cassette housing control assembly.

•

After short-circuiting between TP803 and TP802 pro-

vided at main PWB, plug in the power cord.

•

Checking

Press the play button to set the playback mode.

1. Detach the pinch roller from the capstan shaft.

Do not separate excessively. Or the pinch lever and

pinch double action lever may disengage.

2. Engage the tension gauge adapter with the pinch roller

shaft, and pull in the arrow direction.

3. Gradually return the pinch roller, and measure the pull-

ing force when the pinch roller contacts the capstan

shaft.

4. Make sure that the measured value is within setting

change to 9.8 ± 2N (1.0 ± 0.2kgf).

∗∗∗∗∗

Checking can be perform with or without

cassette housing control.

•

Remove the cassette housing control assembly.

•

After short-circuiting between TP803 and TP802 pro-

vided at main PWB, plug in the power cord.

•

Setting (without cassette housing control)

1. Turn off the power switch.

2. Open the cassette tape (E-180), and fix with tape.

3. Set the cassette tape in loading state.

4. Put the weight (500g) on the cassette tape.

5. Turn on the power switch.

6. Make the adjustment with the beginning of a E-180 tape.

∗∗∗∗∗

Checking can be perform with or without

cassette housing control.

• Setting (with cassette housing control)

1. Insert cassette tape (E-180).

2. Make the adjustment with the beginning of a E-180

tape.

Содержание VC-G200SM

Страница 103: ...103 VC G20SM G200SM VC G201SM G401SM ...

Страница 104: ...104 VC G20SM G200SM VC G201SM G401SM SIGNAL FLOW BLOCK DIAGRAM SIGNALVERLAUF BLOCKSCHALTBILD ...

Страница 106: ...106 VC G20SM G200SM VC G201SM G401SM AUDIO BLOCK DIAGRAM AUDIO SCHALTKREIS BLOCKSCHALTBILD VC G20SM G201SM G401SM ...

Страница 107: ...107 VC G20SM G200SM VC G201SM G401SM EE Signal PB Signal REC Signal E E Signal Wiedergabe signal Aufnahme sihnal ...

Страница 108: ...108 VC G20SM G200SM VC G201SM G401SM AUDIO BLOCK DIAGRAM AUDIO SCHALTKREIS BLOCKSCHALTBILD VC G200SM ...

Страница 109: ...109 VC G20SM G200SM VC G201SM G401SM EE Signal PB Signal REC Signal E E Signal Wiedergabe signal Aufnahme sihnal ...

Страница 110: ...110 VC G20SM G200SM VC G201SM G401SM POWER CIRCUIT BLOCK DIAGRAM HAUPTSTROMKREIS BLOCKSCHALTBILD ...

Страница 113: ...113 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 115: ...115 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 117: ...117 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 119: ...119 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 123: ...123 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 125: ...125 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 127: ...127 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 143: ...143 VC G20SM G200SM VC G201SM G401SM ...