10

VC-G20SM/G200SM

VC-G201SM/G401SM

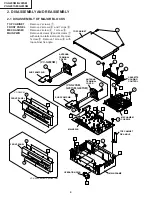

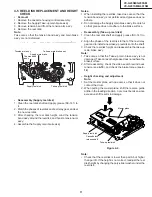

Figure 4-1.

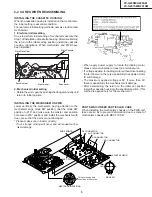

• Reassembly

1. Before installing the cassette housing control, short-

circuit between TP803 and TP802 provided at main

PWB, press the eject button. The master cam turns and

stop in eject position. Fit the drive lever to master cam

through main chassis, push down and slide the drive

lever towards to master cam.

*Eject position: Pinch Drive Cam positioning hole paral-

lel to center of Synchro Gear (Synchro gear marking

line). Synchro Gear positioning mark parallel to center

of master cam.

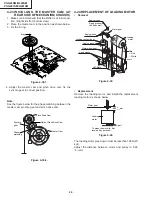

Figure 4-2.

2. Install in the reverse order of removal.

Notes

1. In the case when you use the magnet screw driver, never

approach the magnet driver to the A/C head, FE head,

and drum.

2. When installing or removing, take care so that the

cassette housing control and tool do not contact the

guide pin or drum.

3. After installing the cassette housing control once per-

form cassette loading operation.

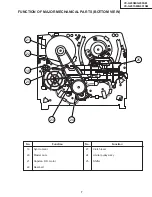

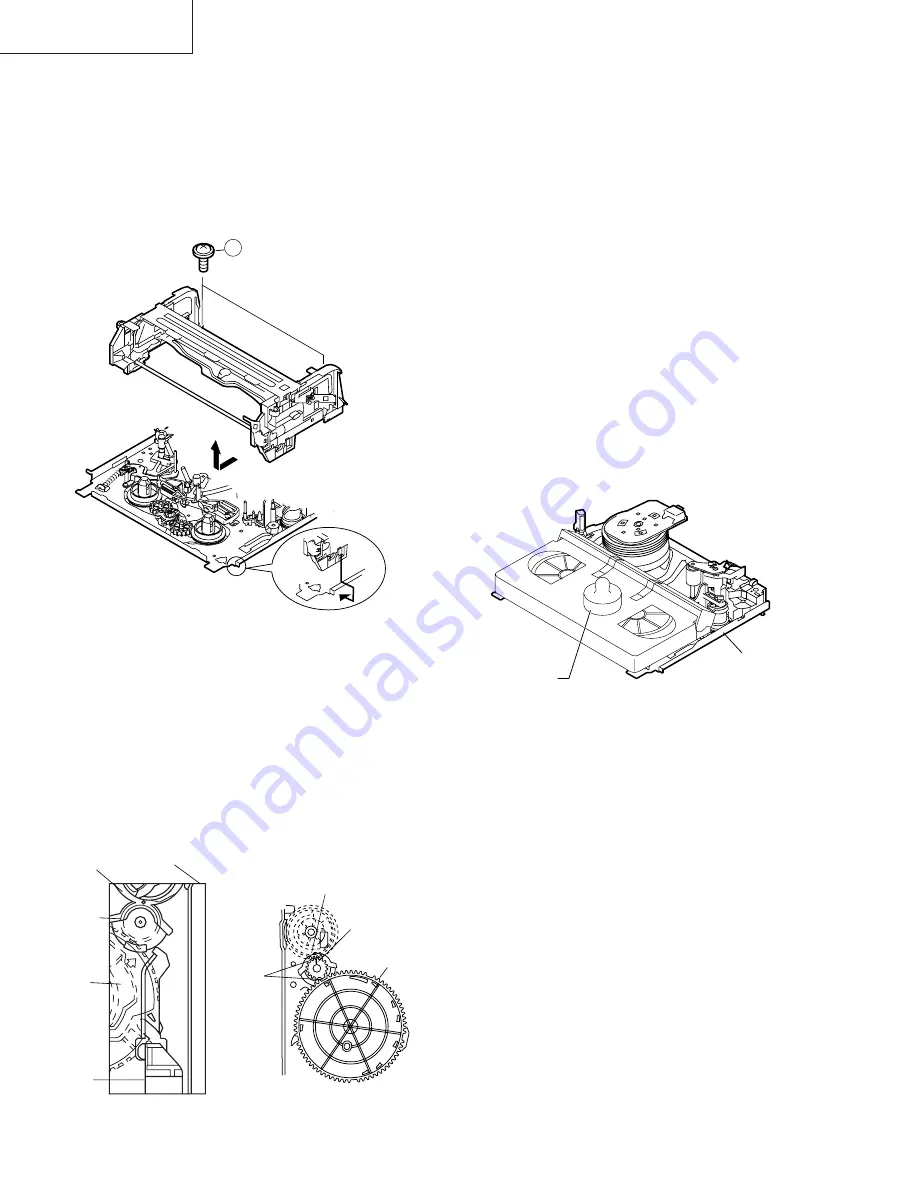

4-4 TO RUN A TAPE WITHOUT THE CASSETTE

HOUSING CONTROL ASSEMBLY

1. Remove the full-surface panel.

2. Short-circuit between TP803 and TP802.

3. Plug in the power cord.

4. Turn off the power switch.

(The pole bases move into U.L.position.)

5. Open the lid of a cassette tape by hand.

6. Hold the lid with two pieces of vinyl tape.

7. Set the cassette tape in the mechanism chassis.

8. Stabilize the cassette tape with a weight (500g) to

prevent floating.

4-3 REMOVING AND INSTALLING THE CAS-

SETTE HOUSING

• Removal

1. In the cassette removing mode, remove the cassette.

2. Unplug the power cord.

3. Remove in the following numerical order.

a) Remove two screws

1

.

b) Pull and circle the drive lever and pull up the cassette

housing control.

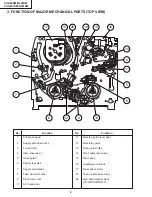

Figure 4-3.

9. Turn on the power switch.

10. Perform running test.

Note:

The weight should not be more than 500g.

To take out the cassette tape.

1. Turn off the power switch.

2. Take out the cassette tape.

1

500g

Weight to prevent

float (500g)

Mechanism chassis

From Bottom View

Pinch Drive

Cam

Synchro

Gear

Master

cam

From top view

Main chassis

Drive

Lever

Phase

matching

Master cam

Line of

synchro

gear.

Hole of Pinch

drive cam.

Содержание VC-G200SM

Страница 103: ...103 VC G20SM G200SM VC G201SM G401SM ...

Страница 104: ...104 VC G20SM G200SM VC G201SM G401SM SIGNAL FLOW BLOCK DIAGRAM SIGNALVERLAUF BLOCKSCHALTBILD ...

Страница 106: ...106 VC G20SM G200SM VC G201SM G401SM AUDIO BLOCK DIAGRAM AUDIO SCHALTKREIS BLOCKSCHALTBILD VC G20SM G201SM G401SM ...

Страница 107: ...107 VC G20SM G200SM VC G201SM G401SM EE Signal PB Signal REC Signal E E Signal Wiedergabe signal Aufnahme sihnal ...

Страница 108: ...108 VC G20SM G200SM VC G201SM G401SM AUDIO BLOCK DIAGRAM AUDIO SCHALTKREIS BLOCKSCHALTBILD VC G200SM ...

Страница 109: ...109 VC G20SM G200SM VC G201SM G401SM EE Signal PB Signal REC Signal E E Signal Wiedergabe signal Aufnahme sihnal ...

Страница 110: ...110 VC G20SM G200SM VC G201SM G401SM POWER CIRCUIT BLOCK DIAGRAM HAUPTSTROMKREIS BLOCKSCHALTBILD ...

Страница 113: ...113 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 115: ...115 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 117: ...117 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 119: ...119 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 123: ...123 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 125: ...125 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 127: ...127 10 11 12 13 14 15 16 17 18 19 VC G20SM G200SM VC G201SM G401SM ...

Страница 143: ...143 VC G20SM G200SM VC G201SM G401SM ...