9

SX51LF7

SX51LF8

9-1

9-2

PURITY

ADJUSTMENT

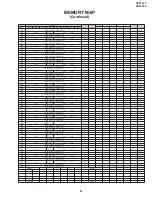

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

PURITY

ADJ.

1

.

Receive the GREEN-ONL

Y

signal.

Adjust the

beam current to ~700 µA.

2

.

Degauss the CR

T

enough with the degausing coil.

Note:

Follow the Job Instruction Sheet to ad-

just the magnetic field.

V

ertical Bv:

+0.030 mT (0.30 gauss)

Horizontal

Bh:

+0.020 mT (0.20 gauss)

(Reference: page E-13)

3.

Maintain the purity magnet at the zero magnetic

field and keep the static convergence roughly

adjusted.

4

.

Observe the points a, b as shown in Fig. 4-1

through the microscope.

Adjust the landing to the

A rank requirements.

5.

Orient the raster rotation to 0 eastward.

6.

T

ighten up the deflection coil screws.

»

T

ightening torque: 108 ± 20 N (1

1 ± 2 kgf)

7.

Make sure the CR

T

corners landing meet the

A

rank requirements. If not, stick the magnet sheet

to correct it.

Note:

T

h

is

a

d

ju

s

tment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 700 µA.

Note:

Set the service mode by TP1001 &

TP1002 (short) then press factory proc-

ess R/C RGB key to change to RGB

mono colour mode.

*

For the following colours press R/C RGB key to

change.

1

a

b

A

B

A

30mm

30mm

B

A = B

A = B

Rank "A"

(on the right of the CRT)

Rank "A"

(on the left of the CRT)

Fig. 4-1

Fig. 4-2

Fig. 4-3

*

Press R/C RGB key for 1 sec-

ond in NORMAL MODE, the

colour will change to RGB

mono colour mode.

T

ext Key “ R.G.Cy “ Key can be

directly use to change to other

colours screen.

Signal-colour

screen cleared

GREEN

ONLY

BLUE

ONLY

RED

ONLY

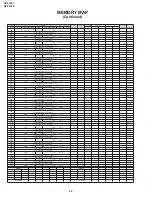

CONVERGENCE ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

CONVERGENC

ADJ.

( T

o

be done

after the purity

adjustment.

1.

Receive the "Crosshatch Pattern" signal.

2.

Using the remote controller

, call NORMAL

mode.

Static convergence

1.

T

urn the 4-pole magnet to a proper opening an-

gle in order to superpose the blue and red col-

ours.

2.

T

urn the 6-pole magnet to a proper opening an-

gle in order to superpose the green colour over

the blue and red colours.

Dynamic convergence

1

.

Adjust the convergence on the fringes of the

screen in the following steps.

a

)

Fig. 5-1: Drive the wedge at point "a" and swing

the deflection coil upward.

b)

Fig. 5-2: Drive the wedge at points "b" and "c"

and swing the deflection coil downward.

c)

Fig. 5-3: Drive the "c" wedge deeper and swing

the deflection coil rightward.

d)

Fig. 5-4: Drive the "b" wedge deeper and

swing the deflection coil leftward.

2.

Fix all the wedges on the CR

T

and apply glass

tape over them.

3.

Apply lacquer to the deflection yoke lock screw

,

magnet unit (purity

, 4-pole, 6-pole magnets) and

magnet unit lock screw

.

Finally received the Red-only and Blue-only sig-

nals to make sure there is no other colours on the

screen.

1

RGB

BGR

R

G

B

R

G

B

B

G

R

B

G

R

RGB

BGR

Lacquer

Wedge "a"

Wedge

"b"

Wedge

"c"

About

100Deg

About

100Deg

4-pole magnet

6-pole magnet

CRT neck

20mm

Lacquer

Purity magnet

Fig. 5-1

Fig. 5-2

Fig. 5-3

Fig. 5-4

Fig. 5-5

Fig. 5-6

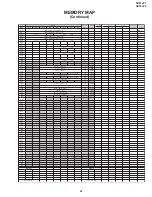

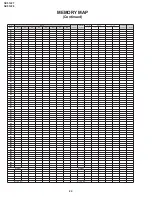

Содержание SX51LF7

Страница 31: ...31 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J CHASSIS LAYOUT ...

Страница 38: ...42 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J SCHEMATIC DIAGRAM MODEL SX51LF7 CRT Unit ...

Страница 39: ...43 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J SCHEMATIC DIAGRAM MODEL SX51LF8 CRT Unit ...

Страница 43: ...50 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J BLOCK DIAGRAM 2 3 CRT IGR BLOCK SX51LF7 ...

Страница 44: ...51 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J BLOCK DIAGRAM 3 3 NICAM IGR BLOCK SX51LF8 ...