10

SX51LF7

SX51LF8

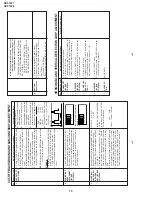

10-1

10-2

CUT

-OFF

, BACKGROUND

AND SUB-CONTRAST

ADJUSTMENT

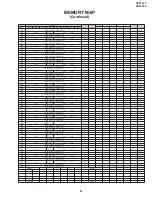

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

CRT CUT

OFF

ADJUSTMENT

1

.

Switch

TV to VIDEO mode,BLUE BACK OFF

, with-

out VIDEO signal.

2.

Press R/C to set Picture Normal condition.

3.

First of

f the screen by adjust screen variable re-

sistor

.

*4

.

Next, check

AKB circuit function by slowly increase

screen variable resistor until colour raster suddenly

On and Of

f (AKB start function).

5.

Then continue adjust unfil retrace line appear

.

6.

Finally

, slowly decrease the screen variablu resis-

tor unfil screen retrace line (Not Raster) Cut Of

f.

*NOTE

: Must comfirm the

AKB function in set before

continue the next adjustment.

REMARK:

1

.

Before CR

T

Cutof

f adjustment, SUB-BRIGHT

, DRI-

RS/RC/R

W

, DRI-GS/GC/GW

, DRI-BS/BC/BW

,

CUT

-R and CUT

-G must be in initial data.

2.

CR

T

Cutof

f adjustment must be done inside a dark

room.

1

20mS

3.0 0.1 Vdc

0

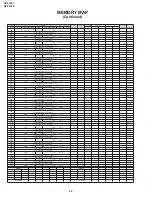

SUB-BRIGHT

-

NESS

ADJUSMENT

(I2C BUS

CONTROL)

1

.

Call " SUB-BRI" in service mode. (Receive Cross-

hatch pattern with 5 black level windows)

2.

Adjust the " SUB BRIGHT " bus data in order that

the line 1 and 2 have the same darkness whereas

line 3 is one step (data) brighter than line 2 .Fi-

nally data minus 1 to make line 1,2 and 3 are in

same level darkness.

2

1 2 3 4 5

1

1 2 3 4 5

2

line 3 is one step (data) brighter

than line 2.

WHITE BAL-

ANCE SER

V

-

ICE MODE

ADJ. (I2C BUS

CONTROL)

1

.

Receive the "WHITE" pattern with BURST SIGNAL.

2.

Press R/C to set Picture NORMAL condition.

3.

Connect the DC miliammeter between the

TP602

(-) TP603

(+).

4.

Check Beam current should be around 1,350 µA.

5.

Set it to service mode and adjust the " DRI-GS"

(White Point-G), "DRI-BS" (White Point-B) data

to have a colour temperature of 12,300°K (white).

* Note .

6.

Receive "White" pattern, with BURST signal, and

set Brightness

Y

by generator

, to **10cd/m

2

(Minolta CA-100) by reducing Luminate

Y

signal.

7

.

Adjust "CUT

-R" & "CUT

-G" to get 12,300°K .

Then

go back normal mode (High Bright**) to check

colour temperature. If out of range, back to 5.

3

*12300°K

X: 0.272

Y

: 0.275

(MINOL

T

A

COLOUR

ANAL

YZER

CA-100)

*Note:

Above Data can be UP/

DOWN by V

olume key

.

Low

High

**Note:

10cd/m

2

180cd/m

2

*Alternative Procedure:

(1).

Step (1),(2),(3) and (4) are same

as beside procedure.

(2).

Then continue adjust until re-

trace appear and make sure the

colour appear wheather red,

green or blue

(3).

Connect the oscilloscope to re-

lated test points as below which

is based on colour appear at (2)

Colour Appear

T

est

Point

RED

TP 851

GREEN

TP 852

BLUE

TP 853

(4).

Then adjust SCREEN VR until

the tip of signal reach

3Vdc±0.1Vdc

HORIZONT

AL

AND VERTICAL

DEFLECTION LOOP

ADJUSTMENT

No.

Adjusting point

Adjusting procedure/conditions

W

aveform and others

V

-LINEARITY

(I2C BUS

CONTROL)

V

-CENTER

(I2C BUS

CONTROL)

V -

AMP

(I2C

BUS CON-

TROL)

H-CENTER

(I2C BUS

CONTROL)

S-CORREC-

TION

1.

Receive Monoscope Pattern Signal.

2.

Call the "V

-LIN" mode.

3.

Increase or decrease "V

-LIN" by V

olume key till

the horizontal line in the center of monoscope is

just at the position where the blanking starts.

1.

Call the "V

-CENT" mode.

2. Increase or decrease "V

-CENT" by V

olume key

till the picture is centered.

1.

Call the "V

-AMP" mode.

2.

Increase or decrease "V -

AMP" by V

olume key

to set overscan of 8.5% typical.

Adjustment Spec 8.5% range +1% -1%.

1.

Call the "H-CENT" mode.

2.

Increase or decrease "H-CENT" by V

olume key

to center the picture horizontal.

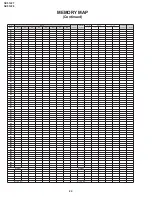

24(FIX DA

T

A

)

1

2

3

4

5

Maximum

beam check

1.

Receive the "Monoscope Pattern" signal.

2.

Press R/C to set Picture NORMAL condition.

3.

Connect the DC miliammeter between

TP603 (+)

and TP602

(–).

(Full Scale: 3 mA Range)

4.

Beam current must be within 1,350 ± 100 µA.

4

Note:

T

h

is

a

d

justment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 700µA).

*

ADJUST

DRI-GC/GW

, DRI-BC/BW

AS FOLLOW

-

ING DA

T

A,

AFTER FINISHING DRI-GS

AND DRI-

BS. *(12300ºK)

DRI-GC/GW DA

T

A

= “DRI-GS”-7 DA

T

A

DRI-RC = 25; DRI-BC = DRI-BS; DRI-R

W = 32

DRI-BW DA

T

A

= “DRI-BS”-7 DA

T

A

Содержание SX51LF7

Страница 31: ...31 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J CHASSIS LAYOUT ...

Страница 38: ...42 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J SCHEMATIC DIAGRAM MODEL SX51LF7 CRT Unit ...

Страница 39: ...43 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J SCHEMATIC DIAGRAM MODEL SX51LF8 CRT Unit ...

Страница 43: ...50 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J BLOCK DIAGRAM 2 3 CRT IGR BLOCK SX51LF7 ...

Страница 44: ...51 SX51LF7 SX51LF8 1 2 3 4 5 6 7 8 9 10 A B C D E F G H I J BLOCK DIAGRAM 3 3 NICAM IGR BLOCK SX51LF8 ...