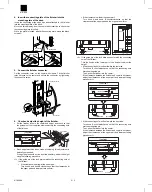

(Operation of stapling)

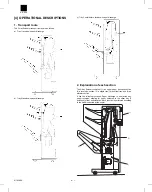

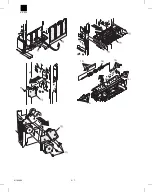

Jogging in lateral direction

1) The jog plates are moved to the stand-by position before the

paper is fed to the staple tray.

2) Immediately after the paper is fed into the staple tray, the jog plate

is moved to the paper size position to ensure the alignment of the

paper.

Staple unit movement at the time of stapling (1-point

stapling)

1) The stapler unit is moved to the stapling position.

– The number of sheets to be stapled is fed to the staple tray –

2) The pusher (the sheets to be stapled) is lowered to the stapling

position.

3) The paper is stapled ... (in the case of 2-point stapling, the action

that is described on the following page is added.)

4) The pusher (the sheets stapled) is elevated to the paper discharge

position.

5) After the job, the stapler unit is returned to the home position.

Stapler unit movement at the time of stapling

(2-point stapling action is added.)

1) The pusher is elevated to the position which makes it possible for

the staple unit to move.

2) The staple unit is moved to the staple position where the 2nd

staple is driven.

3) The pusher (sheets to be stapled) is lowered to the stapling posi-

tion.

4) Sheets are stapled.

5) The staple unit is returned to the 1st staple position.

(After the job is finished, the staple unit is returned to the home

position.)

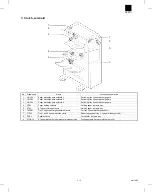

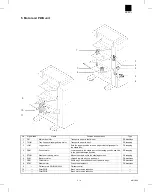

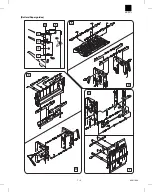

D. Off-set tray

1) Off-set motor (3)

When the off-set motor (3) is driven, the tray is shifted sideways

against the direction in which the sheets are delivered, so that the

sheets discharged into the off-set tray (1) are sorted by the specified

number of sheets. The rotation is unidirectional and controlled by the

crank. The motor is stopped by the off-set home position sensor (2)

turning ON.

No.

Signal name

Part name

(1)

—

Tray 3 (Off-set tray)

(2)

OFHP

OFHP Off-set home position sensor

(3)

OFM

Off-set motor

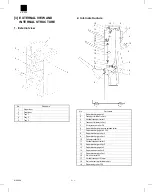

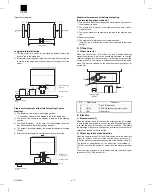

E. Elevator

1) Elevator motor (3)

When the elevator motor (3) is driven, the winding pulley (5) is rotated

in both forward and reverse to wind up the wire (6) stretching vertical-

ly so that the tray 3 (off-set tray) is moved up and down. This allows

the discharge of paper at a fixed position according to the number of

sheets to be loaded on the off-set tray.

2) Off-set tray full and load detection

When the power is turned ON, the off-set tray lowers to the lower limit

sensor (4) position. Then it elevates until the upper limit sensor (7)

turns ON, while counting the encoder pulses of the elevator motor (3).

The volume of paper loaded on the off-set tray is calculated (0 -

100%) by counting the number of pulses from the elevator encoder

(1).

The off-set tray is judged to be full when both the lower and upper

limit sensors (4), (7) are turned ON.

1)

2)

2)

1)

Jog plate

R

Jog plate

F

Pusher

Paper size

5)

1)

3)

2)

4)

Pusher

Staple unit

Home

position

Paper discharge

position

Staple position

ST rail

Staple unit moving

motor

3)

4)

2)

5)

1)

Pusher

Staple unit

moving range

Staple position

ST rail

Staple unit moving

motor

(3)

(2)

(1)

Moving range

(30 mm)

AR-FN3

8/19/1999

4 – 3

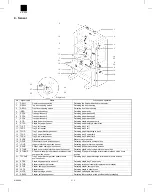

Содержание AR-FN3

Страница 20: ...15 15 15 15 16 AR FN3 8 19 1999 5 7 ...

Страница 27: ... Rollers Paper guides AR FN3 7 2 8 19 1999 ...

Страница 28: ...AR FN3 8 19 1999 7 3 ...

Страница 29: ... Gears Others Sensors Belts AR FN3 7 4 8 19 1999 ...

Страница 51: ...3 Main PWB page arrangement 1 2 AR FN3 10 9 8 6 1999 ...

Страница 52: ...Main PWB page arrangement 2 2 AR FN3 8 6 1999 10 10 ...