Chapter 2

Cone-Fire

In this chapter you will learn to . . .

G

See witness cones at high temperatures

G

Program a Cone-Fire program in minutes

G

Pre-heat the ware so it doesn’t explode

G

Bend a cone by adding extra hold time

G

Cool slowly (called down fire) to alter glazes

Cone-Fire mode is based on Orton pyro-

metric cones. It is not designed for heat

treating, glass fusing and enameling. For

these firings, see “Ramp-Hold,” pages

12-15. Use Ramp-Hold to fire ceramic

pieces that require a custom firing

schedule, such as some types of stone-

ware sculpture or crystalline glaze.

Before using Cone-Fire mode, read all of

this chapter. Have your controller in

front of you so you can try out the keys as

you read. For more details on pyrometric

cones, please see your kiln manual.

Pyrometric Witness Cones

Question

A cone 5 firing was 7°F below the target

listed in your manual, and a cone 6 firing was 22°F

below the target. Is this typical and okay? Is the dig-

ital controller on my kiln operating normally even

though it did not achieve the controller tempera-

tures that were programmed at cone 5 and 6?

Answer

This is normal for Cone-Fire operation. If

the kiln fires slower than the normal rate, it will

shut off at a lower temperature. If the kiln fires

faster than a normal rate, it will shut off at a higher

temperature, sometimes by only a few degrees.

The Sentry Xpress controller shuts off automatically

without cones. Nevertheless, every ceramic firing should

include at least one witness cone (also called the shelf

cone). The witness cone is placed inside the kiln. The wit-

ness cone is the most accurate measurement of heat work in

a ceramic firing.

If you fire the same size load and type of ware regularly,

the witness cones let you compare one firing to the next and

alert you when something is wrong. For example, if the wit-

ness cone bends farther and farther with each consecutive

firing, this may indicate thermocouple temperature drift.

Note:

If the bending of the witness cone does not

match the Cone-Fire shut-off, you may want to ad-

just Cone Offset (page 16) or Thermocouple Off-

set (page 20). If the witness cones bend inconsis-

tently from one firing to another, see “Sentry

Troubleshooter,” a separate publication.

How to Position Cones on the Shelf

(for Ceramic Kilns)

Position the witness cones so

you can see them through a

peephole during firing. If the

kiln takes longer than usual to

fire, you may wonder if some-

thing has gone wrong and the

kiln is over-firing. But by seeing

the cones, you will know how the

firing is actually progressing.

If you follow these guidelines,

you should be able to see the

cones even at cone 10:

1

Place the cones 8” - 12”

away from a peephole. Positioning them closer

makes them difficult to see.

2

Have enough space

around the cones to

keep them from touch-

ing a piece of ware

when they bend.

3

Position cones so that

when viewed from the

peephole, they are sil-

houetted by a glowing

heating element on the

o p p o s i t e k i l n w a l l .

(Keep cones at least 2”

from an element.)

4

The element that silhouettes the cones should be

level with the lower part of the cone. If the element

is in line with the upper part of the cone, you won’t

be able to see the cone when it bends.

Sentry Xpress 5 Cone-Fire / Ramp-Hold

8

Do not leave your kiln unattended during operation.

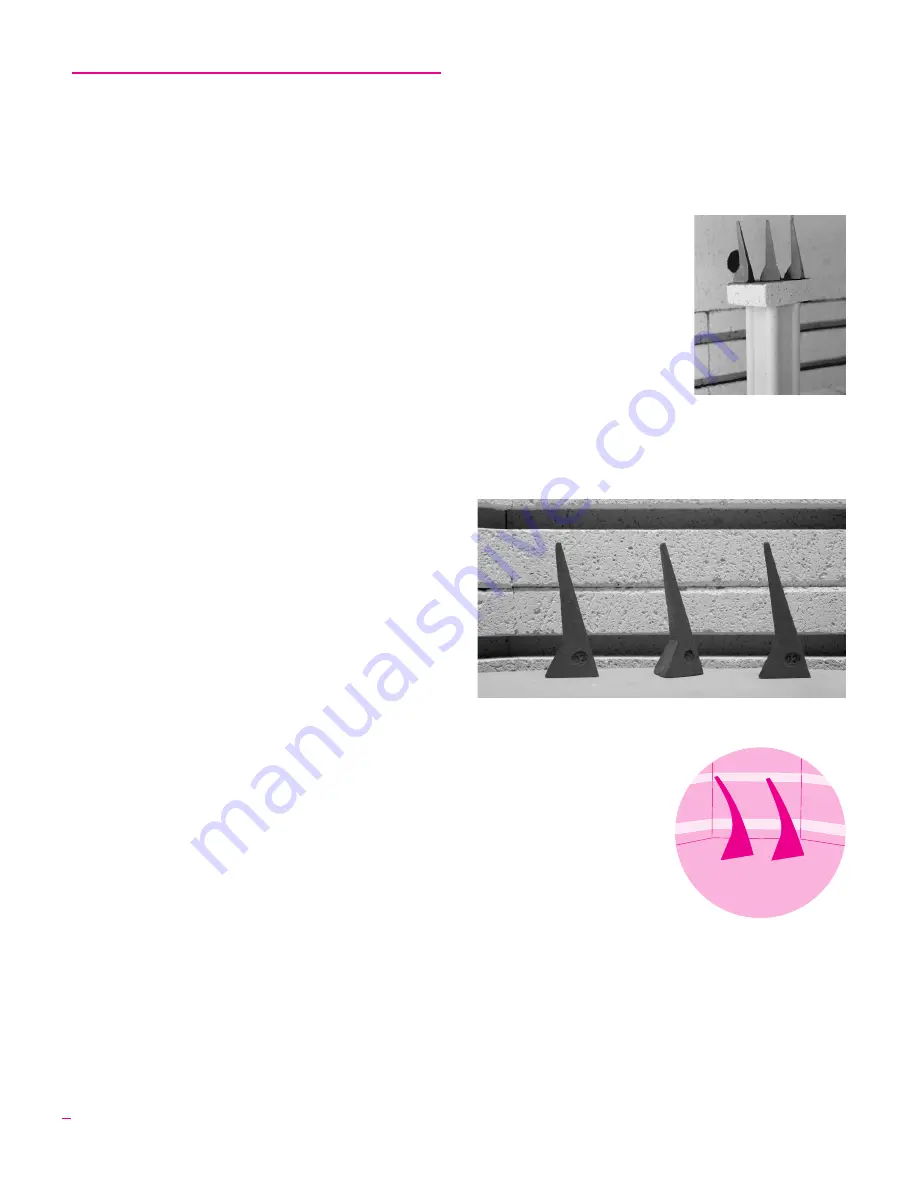

Use self-supporting witness

cones on the shelf. They stand

upright without cone holders.

Silhouette the lower part of the

cone against an element. Keep

the cone 8” - 12” away from the

peephole.

The heating element in the background should be lined up with the lower

part of the witness cones. If the element is too high, the tips of the cones

will disappear from view when they bend.