4

When the original Furlex was introduced in 1983, it was not a pioneering project. We had studied

the market and seen what was already available. We improved the jib furling concept in a number of

ways. Furlex quickly became the market leader, a position it still occupies today. The first systems

sold are still functioning well. Providing ample proof of the design’s effectiveness and long-term

staying power. Our success can also be put down to how we select a system for a specific yacht. First

we calculate the boat’s righting moment, which is the function of its displacement, ballast, beam and

draught. Then we use righting moment in combination with the rig type to calculate its power when

sailing, and the likely loads on the Furlex system. In this way, we achieve a correctly dimension jib

furling system for each individual yacht.

It has always been our intention to retain responsibility for our products through all stages of supply.

Furlex is only sold through authorised local dealers who are able to cover all service requirements for

the customer. Includingassistance with assembly, the modification of sails or the production of new

sails, as well as service.

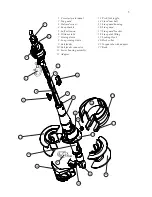

This new Furlex model range, for through-deck mounting, incorporates improvements based on our

extensive experience, and represents the very latest development of the jib furling and reefing concept.

Furlex is supplied as a complete assembly kit containing all the components required.

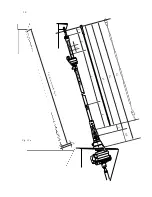

Furlex TD can be split between the lower bearing assembly and the luft extrusion. The lower

bearing assembly with line drum, etc. can be permanently installed in the yacht, even if the luff

extrusion is disconnected.

Furlex TD has a permanently fitted adjusting screw for exact adjustment in relation to the deck

level, which considerably simplifies customising to different boat types.

The halyard swivel features a load distribution system. A unique patented system which

distributes loads over the entire ball race. This permits smoother furling and considerably reduces

bearing wear.

The tack ring’s "free turn" flattens out the sail, promoting an efficient shape when reefed.

Furlex TD is suited to both cruising and racing. With the line drum and line guide unit mounted

below deck, the leading edge of the sail can be maximised along its entire length.

The luff section has two luff grooves, allowing two jibs to be goose-winged when running down

wind. And facilitating fast sail changes for racing yachtsmen.

The aluminium extrusion is insulated from the forestay over its whole length. The extrusion

joining sleeves are also are insulated internally. In order to prevent wear and corrosion.

The line guide fitting centres the line as it is wound onto the drum. The flexible internal line guard

maintains light pressure on the line to ensure even distribution on the drum.

Furlex is manufactured by Seldén Mast, the world’s leading manufacturer of masts and rigging

systems. We wish you fine sailing with your Furlex.

1.2 Product information

Follow the instructions carefully when fitting.