Section 5: Operations

Operating All Models

Sacksafoam I Operator’s Manual

(Version C)

19

Most of these changes are relatively small and, for practical purposes, can be disregarded, particularly at low

concentrations and short run times.

Example:

For a concentration of 0.5% in a model 9011 Bambi bucket, the chart on the top of the control box

shows a run time of 15 seconds. If you are using Silvex, the run time will be 15 seconds minus 20%. The

equation for this is 15 - 3 = 12 seconds.

Note:

Most of these changes are relatively small and, for practical purposes, can be disregarded, particularly

at low concentrations and short run times.

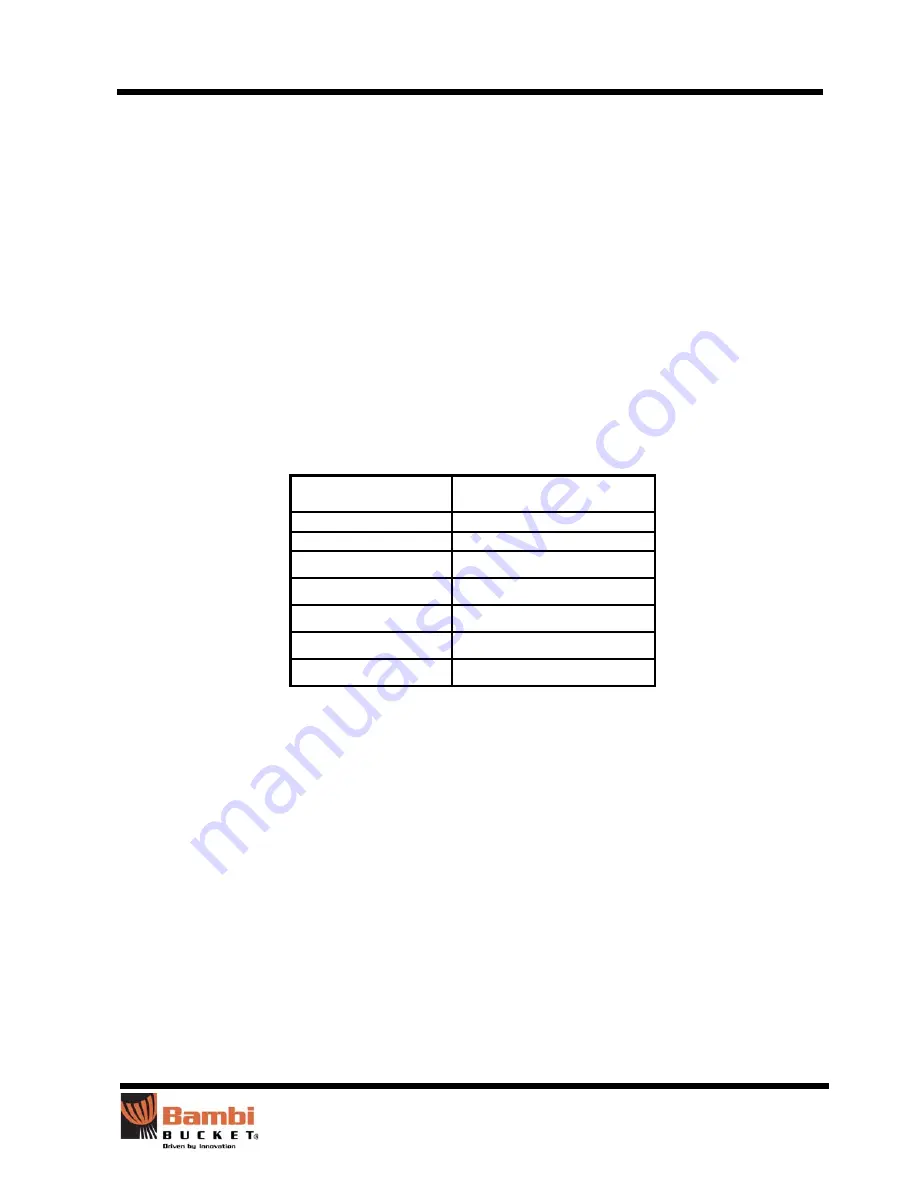

Using Non-Standard Voltages

If it is not possible to obtain 28-volts at the control box when using the supplied wire, or 24-volts at the in-

jection pump when using a long line, adjust the run times as shown in the table below.

Note:

Most of these changes are relatively small and, for practical purposes, can be disregarded, particularly

at low concentrations and short run times.

Removing the Sack from the Bucket

1.

Reverse installation sequence.

2.

If there is any appreciable amount of foam left in the sack, it should be pumped out until the pump

runs dry. At this point the sack can be easily removed from the bucket. The remaining foam

(approximately four litres with the 8018 sack) can be removed through the drain port.

Voltage Variation

(volts)

Change in Run Time

(%)

+1V -2%

+2V -5%

Standard No

change

-1V +3%

-2V +7%

-3V +12%

-4V +19%