Assembly

20

06.00 | NSA plus 120; NSA plus 160 | VERO-S quick-change pallet system | en |

0489070

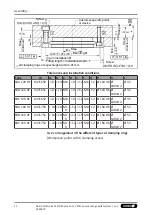

The air connection is made the standard way via the coupling bore

on the lower face side of the quick-change pallet module. For axial

sealing, the O-rings must be inserted in the base-side O-ring seats

of the clamping module.

The accessory kit of the NSA plus 160 contains the Ø 7 x 1.5 (Item

21) O-rings for sealing the bottom hose-free direct connections.

When the turbo connection is used, the spring-actuated locking

procedure is actively supported with air pressure. If the turbo

connection is not used, the relevant side of the piston must be

able to ventilate.

Request our installation drawings if doing the installation yourself.

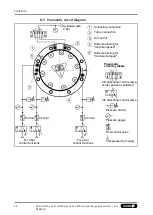

The NSA plus 160 size has an air control, and dynamic pressure

monitoring of the clamping slide position is possible. Via two

separate air connections, the clamping slide position can be

monitored in "OPENED" and/or "CLOSED" status alternately.

The monitoring functions can be monitored via an electronic

pressure switch. A pressure switch signals to the operator or the

machine which position the clamping slides are in or if the

clamping pallet is completely flush and locked.

The air connection for the monitoring functions is done the

standard way via the coupling hose on the lower face side of the

quick-change pallet module.

To do this, remove the M6 x 5 Torx (Item 23) set-screws. For axial

sealing, the O-rings must be inserted in the base-side O-ring seats

of the clamping module.

The Ø 7 x 1.5 (Item 21) O-ring for sealing the air connection is

contained in the accessory kit.

When the turbo connection is used, the spring-actuated locking

procedure is actively supported with air pressure. If the turbo

connection is not used, the relevant side of the piston must be

able to ventilate.