Function

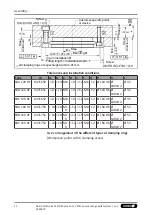

When using this control and cleaning function, it must be ensured

that the clamping ring is in the right position orientation. The

cylinder head countersinks of the clamping ring must not be

positioned on the air outlet holes of the clamping module, since

otherwise the blast air will escape and it will not be possible to

build up a measurable dynamic pressure.

The measurable differential pressure must be minimal 1 bar so

that a reliable evaluation is possible, via the air gap sensor. The

maximum pressure is 2 bar.

For supervision, a pressure gauge, an adjustable throttle and an air

gap sensor are needed.

The clamping modules of a clamping station (connected in parallel

up to a certain number) can be monitored on a pressure switch.

The air connection is made the standard way via the coupling hose

on the lower face side of the quick change pallet module. For

sealing the air connection see chapter "Fastening and

connection"

. Basically the use of the air control

function is not necessary for the operation of the clamping

module.

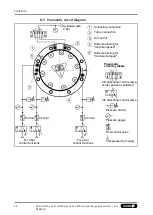

8.4 Dynamic pressure monitoring at the clamping slides

The NSA plus quick-change pallet module features dynamic

pressure monitoring on the clamping slides.

It is therefore possible, for example, to monitor the dynamic

pressure on the clamping slides of the quick-change pallet module

using an electronic pressure switch. This means the slide position

can be monitored electronically in order to ensure that the

clamping slides are in an unlocked position. This way, the clamping

system can be protected from any possible damage.

The measurable differential pressure must reach a minimum of

1 bar for assessment via the air gap sensor to be reliable. The

maximum pressure is 2 bar.

Monitoring requires a pressure gauge, an adjustable throttle and

an air gap sensor.

The air connection is made the standard way via the coupling bore

on the lower face side of the quick-change pallet module. Sealing

the air connection (please refer to chapter "Fastening and

connection"

). Use of the dynamic pressure monitoring

function is not mandatory for the basic operation of the clamping

module.

In a clamping station with up to 4 clamping modules, the clamping

slide monitoring functions "Module open" and "Module clamped"

can each be switched in parallel and monitored at a pressure

switch for the respective function.

27

06.00 | NSA plus 120; NSA plus 160 | VERO-S quick-change pallet system | en |

0489070