45

AIR COMPRESSOR - OWNER'S MANUAL

TECHNICAL DATA 20120HWV80X

4

3

2

6

7

11

10

3

4

2

18

16

33

19

25

26

18

27

28

30

1

38

37

31

21 - 45

34

24

23

14

20

20

9

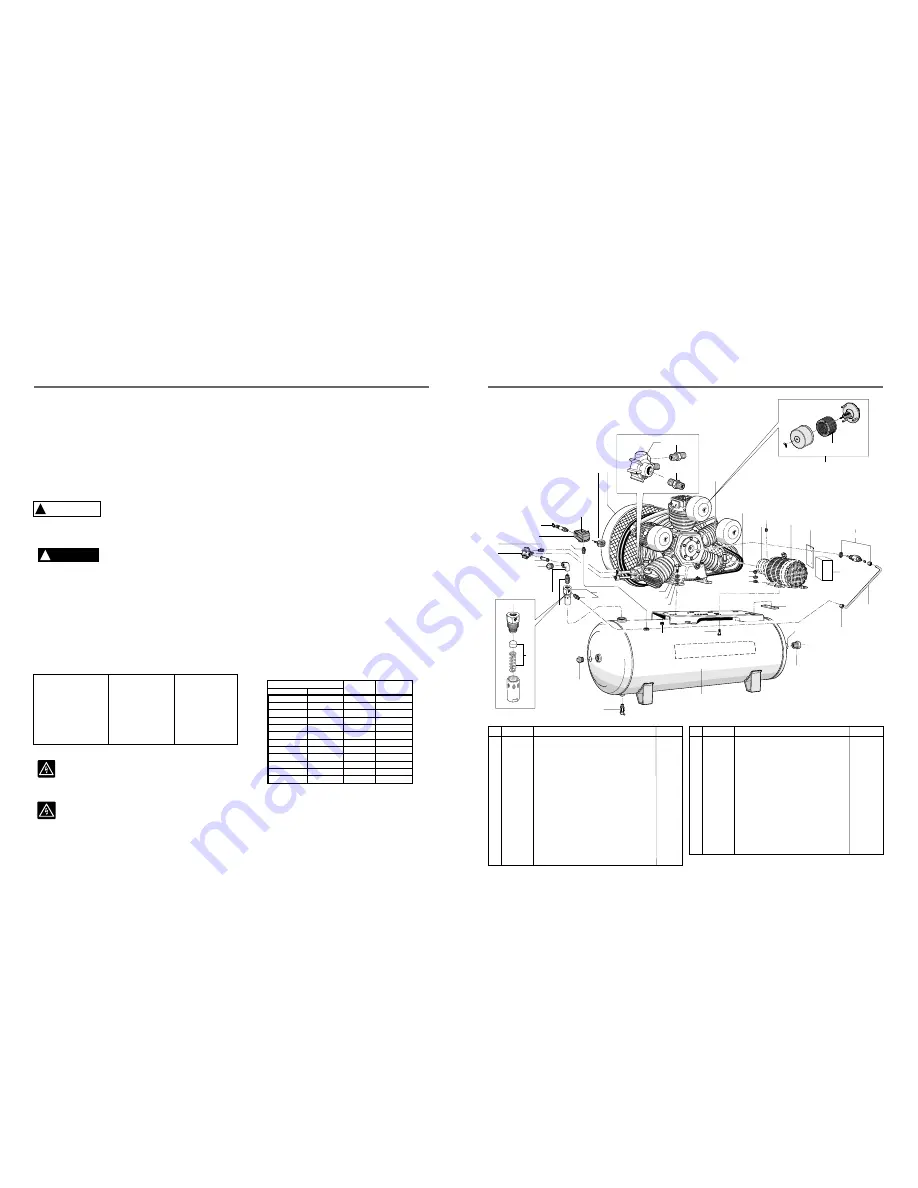

AIR COMPRESSOR PARTS

2 x 1 reduction bushing

1/4 tube

Centrifugal unloading valve

Centrifugal unloading valve kit

Motor 208/230/460V (three-phase)

Belt

Motor fastening plate

7/16 x 1.3/4 hex head bolt

7/16 hex nut

1/2 lock washer

1/2 washer

Pulley

3/8 x 1/2 Allen hex without head

Start switch**

Support start switch**

Start switch pressure switch cord (not shown)**

Motor start switch cord (not shown)**

3/4 NPT air filter

Filter element

Hose for tank drain (not shown)

CODE

QTY

DENOMINATION

01

01

01

01

01

02

02

04

04

08

08

01

01

01

01

01

01

03

03

01

No.

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Bare pump

3/4 nipple

NPT 3/4 x 1/2 straight connection

Upper tubing adaptor

Belt guard

Pressure gauge

Pressure switch

1/4 nipple

Strain relief

1/4 ASME safety valve

3/4 x 126mm nipple

3/4 side elbow

3/4 plug

Check valve

Check valve kit

NPT 1/8 x 1/4 straight connection

2 Plug

O - ring

1/4 tank drain valve

W 1/2 x 1.1/2 hex head bolt

BSW 1/2 hex nut

120 gal horiz. Tank

CODE

QTY

DENOMINATION

933.9385-0

003.0036-5

21011001

20517005

830.1023-0

011.0118-0

012.0845-0

003.0174-4

012.0723-0

022.0057-0

21011006

003.0343-0

003.0031-4

60281501

34004508

003.0054-3

003.0514-0

023.0339-0

022.0185-0

*

*

25003832A

01

02

04

02

01

01

01

01

01

01

01

01

01

01

01

01

01

02

01

04

04

01

No.

1

2

3

4

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

23

24

25

003.0512-0

709.1671-0

022.0174-0

830.1043-0

015.0604-0

004.0022-0

21028539

*

*

*

*

709.1349-0

*

012.0941-0

701.0381-0

012.0907-0

012.0910-0

809.1085-0

007.0118-0

709.1246-0

* Part available in the market - not sold by Schulz.

** Optional start switch

29

39

36

15

35

35

36

40

44

43

17

8

13

32

AIR COMPRESSOR - OWNER'S MANUAL

4

INSTALLATION

Wiring -

pressure switch

Before starting the installation procedure, check that the building's electrical service has an adequate

capacity to handle the motor and the same electrical characteristcs (voltage, cycle, and phase). Install the compressor

as close to the main power supply as possible and follow all National Electric Safety Codes as well as those dictated

by State and Local authorities. A qualified electrician must do the electrical installation. Every compressor model has a

specific power requirement and the wire size used is critical to a proper installation. The two tables (shown below) are

for reference only and should not supersede specific National, State or Local code requirements. The compressor can

be mannufactured without a

, according to the product version.

power switch

The

must not be

directly connected to the motor but to a control circuit. See "Electrical Diagram" page 5 and 6 to correct

installation, according to the product version.

Piping -

The main distribution line should not be any smaller than the pipe size of the shut off valve of the compressor. It is

recommended that the shop air system be connected to the air compressor shut off valve with a flexible coupler to reduce

the risk of damage from vibration. All airlines should slope to an accessible drain or moisture trap for removal of

condensation. Make sure that there are no leaks in the airlines as even small leaks can cause your compressor to run

outside of the rated duty cycle. A typical installation is shown on page 11, note that the feeder lines come off of the top of the

main distribution line so that moisture can't enter the feeder line.

WARNING

!

ASME coded pressure vessels must not be modified, welded, repaired, reworked or

subjected to operating conditions outside the nameplate ratings. Such actions will negate

code status, affect insurance status and may cause severe personal injury, death and

property damage.

DANGER

!

High voltage may cause personal injury or death. Disconnect and lockout/tagout per

O.S.H.A. Regulation 1910.147 all electrical power supplies before opening the electrical

enclosure or servicing.

30 amp circuit

0-30 ft.

31-50 ft.

51-70 ft.

10 ga

8 ga

6 ga

71 ft and up:

call factory

40 amp circuit

0-25 ft.

26-50 ft.

51-75 ft.

8 ga

6 ga

4 ga

76 ft and up:

call factory

60 amp circuit

0-10 ft.

11-30 ft.

31-50 ft.

8 ga

6 ga

4 ga

51 ft and up:

call factory

Air Intake -

Do not locate the compressor where it could ingest toxic, volatile or corrosive vapors or extremely dirty air. If a

remote inlet filter is going to be installed you must increase one pipe size for every ten feet in length and use a flex hose

between the pump and any solid pipe to minimize the potential of damage from vibration.

Grounding instructions:

This product must be

grounded to reduce the risk of an electric shock. Connect

the Grounding cable to the motor's terminal, or if there is

no terminal to the motor's frame.

The incorrect installation of the grounding wire connector may result in an electric shock. If it is

necessary to replace or repair both the cable and the connector, do not connect or join the grounding wire

to the neutral wire or other. The green wire, with or without yellow stripes, is only to the grounding

function. In case of doubts regarding the grounding information or whether the product is properly

grounded, make sure you contact a qualified electrician to verify the connections.

WARNING

Motor power [ hp ]

single-phase

three-phase

Input supply

voltage [V]

Max.fuse

(gL/gG)* [A]

3

5

-

7.5

-

-

-

-

-

-

-

-

-

-

5

-

7.5

7.5

10

10

15

15

20

20

230

230

460

230

230

460

230

460

230

460

230

460

50

35

20

80

50

25

63

35

100

50

100

63

Orientative table for fuses

* type 2 coordination

Orientative table for wiring