II/6

UNM

GB

2.9 Warranty

Basic principle:

complete unit in original

condition / proof of purchase.

Material and production defects are covered

by statutory provisions.

Excluded warranty claims:

Wear/consum-

able parts; improper use; overload; manipu-

lation/use for other than intended use;

insufficient/incorrect/no maintenance; accu-

mulation of dust/dirt; incorrect/impermissi-

ble work methods; failure to observe the

Instruction Manual; incorrect processing/

working materials; incorrect electrical con-

nection; improper installation.

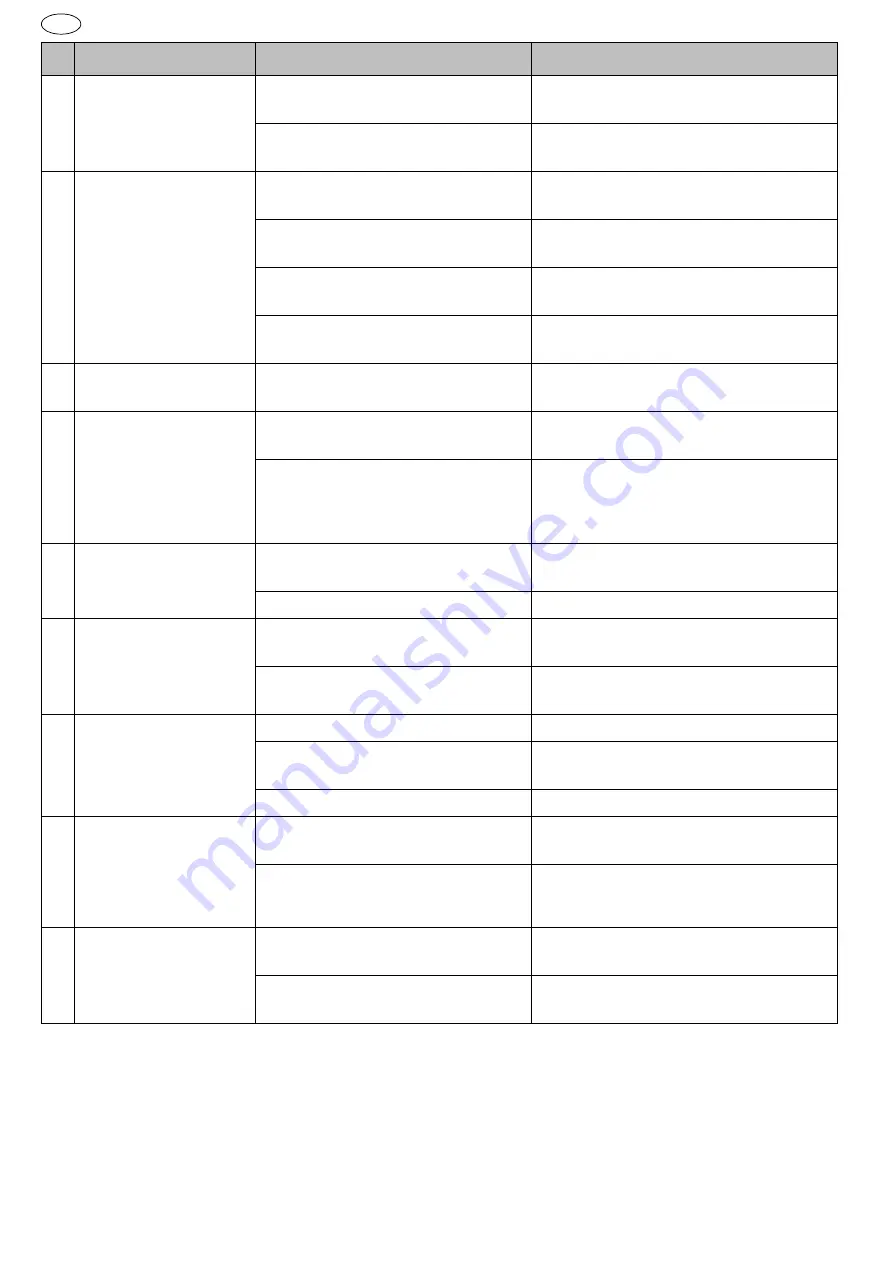

E

Compressor runs

continuously

Intake filter badly contami-

nated

X

Clean or replace

Air consumption of compressed

air tools is too high

X

Check air consumption. Contact

the service partner

E

Compressor runs

continuously

Leakage at compressor

X

Locate leak, contact service part-

ner

Excessive condensate in the

tank

X

Drain the condensate (see

Chap. 2.6.5)

Compressed air line leaky

X

Check the compressed air net-

work, seal leak

Condensate drain valve is open

or missing

X

Close or replace

F

Load-relieving valve

is blowing off

Load-relieving valve leaky

X

Clean or replace

G Switch-off pressure

reached: load-

relieving valve

blows off until

switch-on pressure

is reached

Check valve insert leaky or

defective

X

Clean or replace (see

Chap. 2.6.11)

Check valve is damaged

X

Replace

H Compressor

switches on fre-

quently.

Excessive condensate in the

pressure tank.

X

Drain the condensate (see

Chap. 2.6.5).

Compressor overloaded.

X

See item E

I

Safety valve blows

out.

Vessel pressure is higher than

the set switch-off pressure.

X

Have the pressure switch reset/

replaced by a qualified person.

Safety valve is defective

X

Replace or contact service part-

ner

J

Compressor over-

heats.

Air supply not sufficient.

X

Ensure sufficient ventilation.

Cooling fins on cylinder (cylin-

der head) contaminated

X

Clean

Duty cycle too long.

X

Switch off compressor.

K Oil-lubricated com-

pressor: the oil

level rises without

oil having been

added

Condensate collects in the oil

X

Compressor is too large, contact

service partner

High humidity.

X

Change oil.

L

V-belt driven com-

pressor: unusual

running noises

V-belt or belt disc is scraping

against belt guard grating

X

Look for point of contact, remedy

error

V-belt sags

X

Tighten the V-belt (see

Chap. 2.6.10)

Problem

Cause

Remedy

Содержание A 713 010

Страница 3: ...5a 8a 2a 6a 7a 4a 8b...

Страница 79: ...UNM II 63 RUS 2 3 Schneider Druckluft GmbH 38 2 4 2 4 1 2 4 2 2 4 3 1 2 3 2 6 6 L X X X X X X...

Страница 84: ...II 68 UNM RUS C X X A X D X 2 4 4 E X X X X 2 6 5 X X F X G X 2 6 11 X H X 2 6 5 X E...

Страница 85: ...UNM II 69 RUS 2 9 I X X J X X X K X X L X X 2 6 10...