27

QUICKCAT

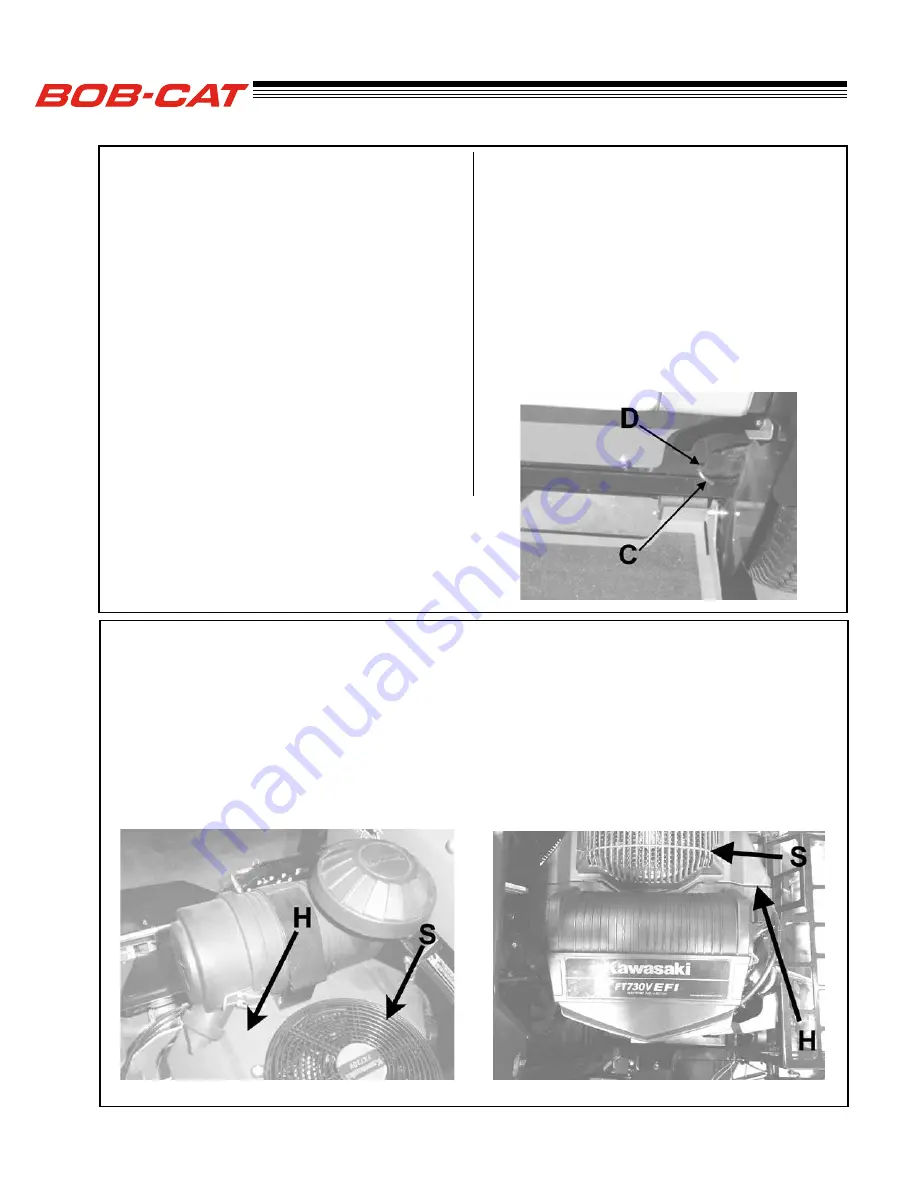

ENGINE COOLING

Continued operation with a clogged cooling system will cause severe overheating and can result in engine

damage.

-

Daily

: Clean air intake screen

S

on air cooled engines.

-

Every 100 hours

: Clean cooling fins beneath blower housing

H

with reference to information in the en-

gine manufacturer's manual.

PURGING TRANSAXLES

Due to the effects air has on efficiency in hydrostatic

drive applications, it is critical that it be purged from

the system.

These purge procedures should be implemented any

time a hydrostatic system has been opened to fa-

cilitate maintenance or any additional fluid has been

added to the system.

Purging may be required if the unit shows any of the

following symptoms:

- Noisy operation.

- Lack of power or drive after short term use.

- High operation temperature, excessive oil

expansion.

1. Check the transaxle fluid, fill to proper level, if

required. Should be to the Full Cold Line.

2. Raise the drive wheels off the ground. Support

unit with jack stands or other suitable means.

3. Open bypass valves. To open the bypass valves,

move the parking brake to any

OFF

position,

then lift and pull bypass control rod

C

through the

large opening

D

, until the control rod stop is past

the opening. Drop rod

C

into the small opening

to lock in place. Repeat for the other bypass

control rod. Start engine, slowly move the control

levers in both forward and reverse directions 5

to 6 times. As air is purged from the unit, the oil

level will drop.

4. With the bypass valve closed, and the engine

running, slowly move the control levers in both

forward and reverse directions 5 to 6 times.

5. Stop engine. Check the transaxle fluid level, add

fluid as required.

6. It may be necessary to repeat steps 3-5 until all

the air is completely purged from the system.

When the transaxle moves forward and reverse

at normal speed, purging is complete.

MAINTENANCE

NON EFI UNITS

EFI UNITS

Содержание BOB-CAT 912480A

Страница 41: ...39 QUICKCAT PARTS SECTION PARTS SECTION ...