User Manual, Power contactors, series CT1115/08 and CT1130/08

Rev. 2.2

Page 6/26

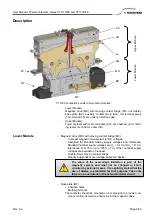

Introduction

CT1000 contactors are air switching components with arc breaking in ce-

ramic. They use a highly sophisticated principle of arc control, combining

the permanent-magnetic and electro-magnetic blow-out technique.

This allows practically unrestricted operation for all AC and DC voltages

and currents within the technical specification.

CT1015 contactors are designed for nominal voltages of 1,500 V.

CT1030 contactors are designed for nominal voltages of 3,000 V.

Due to the very high rated insulation voltage CT1030 contactors

can be used for peak voltages up to 5,000 V.

This manual refers to single pole contactors with a conventional

thermal current of 800 A. For single contactors for 400 A refer to

manual C20/04-M. For single contactors for 1,100 A refer to man-

ual C20/11-M.

CT1000 contactors provide excellent switching performance from very

small up to heavy loads.

CT1000 contactors are available for vertical and horizontal mounting.

CT1000 contactors have been designed and tested according to National

and International Railway Standards. Due to their unique features they

can also be used in a variety of industrial applications.

CT1000 contactors offer the following design-related advantages:

Compact, rugged design

2 voltage levels, several current levels

Double-break contacts, cadmium-free contact tips

1-, 2- (and 3-) pole versions

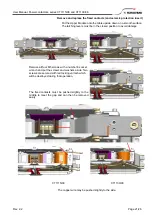

Easy maintenance:

o

Easy inspection of main contact tips, easy replacement of

main contacts

o

Easy replacement of arc chamber (upper module)

Drive system suitable for standard railway supply voltages and

tolerances. No economy circuit required for standard versions.

Drive systems for industrial applications on demand.

Insulation coordination:

o

Functional insulation for main circuit

o

Basic insulation between main circuit and protective earth

o

Reinforced insulation between main circuit and control

circuit / main circuit and auxiliary circuits

Long mechanical and electrical life

No regular maintenance required. Inspection intervals and exchange of

wear parts depending on specific application.