User Manual, Power contactors, series CT1115/08 and CT1130/08

Rev. 2.2

Page 15/26

Electrical requirements

The minimum clearances to earth or other components must be observed.

Refer to the dimensioned drawings for details.

Switching electrical currents at high voltages will produce arcing and plasma

may exit out of the arc chambers. It is essential to observe the minimum

clearance to earth and to the connecting bus bars to avoid the risk of a

flash-over. The minimum clearance has been tested and specified in relation

to the switching capacity of the contactors.

For switching heavy loads allow a minimum time of app. 30 s between

switchings. Allow a recovery time of at least 10 min after 3 heavy load

switchings in succession.

Ensure sufficient ventilation, especially in the case of heavy arc switching.

Allow the exchange of surrounding atmosphere to avoid the risk of flasho-

vers and excessive corrosion.

The minimum gauges for the main terminals and the earth terminal must be

observed. Schaltbau strongly recommends current bars for the connection

of the main terminals with a cross section of 60 x 6 mm.

If wires are being used the wire gauges must be selected in coordination

with their insulation class and the operating conditions.

Undersized gauges for the earth terminal may produce a safety hazard.

Refer to catalogues for the power consumption of the magnetic drive system

and the electrical data of the auxiliary switches.

C20 (Catalogue for Contactors CT1115/04, CT1130/04, CT1115/08,

CT1130/08, CT1115/11 and CT1130/11)

D26 (Catalogue for Snap Action Switches S826)

D70 (Catalogue for Snap Action Switches S870)

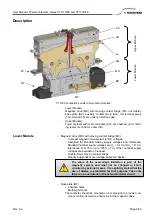

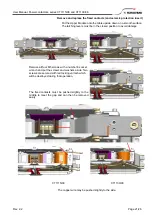

Mechanical installation

Clean the surface of the mounting plate and the base-plate of the contactor

(Lower Module).

Put the Lower Module on the mounting plate and secure with the appropri-

ate screws using the correct tightening torque. Schaltbau strongly recom-

mend Schnorr-Washers (or similar) to secure the screws.

Installation must be carried out by qualified personnel only.