Fire damper BKP-EN

Technical documentation

Spring return actuators

Construction subject to change.

No return possible!

Version: 2020-09-01 | Page 29

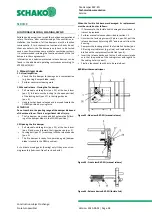

Electric spring return actuator with temperature monitoring

unit

Trigger temperatures: room temperature 72 °C and inter-

nal duct temperature 72 °C optionally 95 °C (for hot air

heating).

Operating position (damper "OPEN") and tensioning of

the return spring by applying the supply voltage.

24V actuators with connectors that can be removed on

site if required.

Safety position (damper CLOSED) through spring force

when supply voltage is interrupted or the temperature

fuses (room temperature; 72 °C or internal duct tempera-

ture; 72 °C optionally 95 °C) respond. The response of the

thermal fuses interrupts the supply voltage permanently

and irrevocably.

Display of the damper end positions is possible by means

of integrated auxiliary switches via potential-free

changeover contacts

(S1 - S3 CLOSED indicates the CLOSED position;

S4 - S6 OPEN indicates the OPEN position).

Technical data S00/S01

S00

(GRA126.1E/SO3)/

S01

(GRA326.1E/SO2)

Table 8: Technical data S00/S01

Manual actuation and fixing in any position is possible in

the de-energised state. It is unlocked manually.

An on-site functional check is possible by means of a

pushbutton or temperature monitoring unit permanently

connected to the actuator.

Spare parts: Duct tip for temperature monitoring unit

with internal duct temperature of 72 °C (ASK79.4) or 95 °C

(ASK79.5).

The replacement takes place by unscrewing both screws

at the temperature monitoring unit and removing the ac-

tuator unit. Pull duct tip (internal duct temperature fuse)

off the temperature monitoring unit and replace it with a

new duct tip with internal duct temperature of 72 °C

(ASK79.4) or 95 °C (ASK79.5). Reinsert temperature mon-

itoring unit into actuator unit and screw it down.

For damage other than to the duct tip (internal duct tem-

perature fuse), the entire actuator/temperature monitor-

ing unit set must be completely replaced.

Actuator type

S00

(GRA126.1E/SO3)

S01

(GRA326.1E/SO2)

Supply [V]

AC 24 / DC 24…48

(SELV/PELV)

AC 230

Operating voltage [V]

AC 24 ±20% /

DC 24…48 ±20%

AC 230 ±15%

Frequency [Hz]

50/60

Power consumption during operation

AC: 5 VA / 3.5 W

DC: 3.5 W

7 VA / 4.5 W

Power consumption in idle position

AC/DC: 2 W

3.5 W

Auxiliary switch

*)

Integrated, fixed switching point at 5° or 80°

Auxiliary switch switching voltage [V]

AC 24…230 / DC 12…30

Auxiliary switch rated current [A]

AC: 6 (ohmic) or. 2 (inductive) / DC: 2

Supply cable

Cable 0.9 m, 2 x 0.75 mm² (halogen-free)

AC 24 V: (wires 1-2)/ AC 230 V: (wires 3-4)

+ 3-pin connector

Auxiliary switch cable (wires S1…S6)

Cable 0.9 m, 6 x 0.75 mm² (halogen-free)

+ 6-pin connector

Motor runtime (angle of rotation 90°) [s]

90

Spring return runtime [s]

15

Protection class

III according to EN 60 730

II according to EN 60 730

Degree of protection according to EN 60

529

IP54

Ambient temperature Normal operation

-32…+50 °C (actuator)

-20…+50 °C (temperature monitoring unit)

Storage temperature

-32…+50 °C (actuator)

-20…+50 °C (temperature monitoring unit)

Ambient humidity

<95% r.h. / no dewing (actuator)

CL D according to DIN 40040 (temperature monitoring

unit)

*) Either only mains voltage or only safety extra low voltage may be applied to the auxiliary switches. Mixed operation is not allowed. Operation with

different phases is not allowed.