6

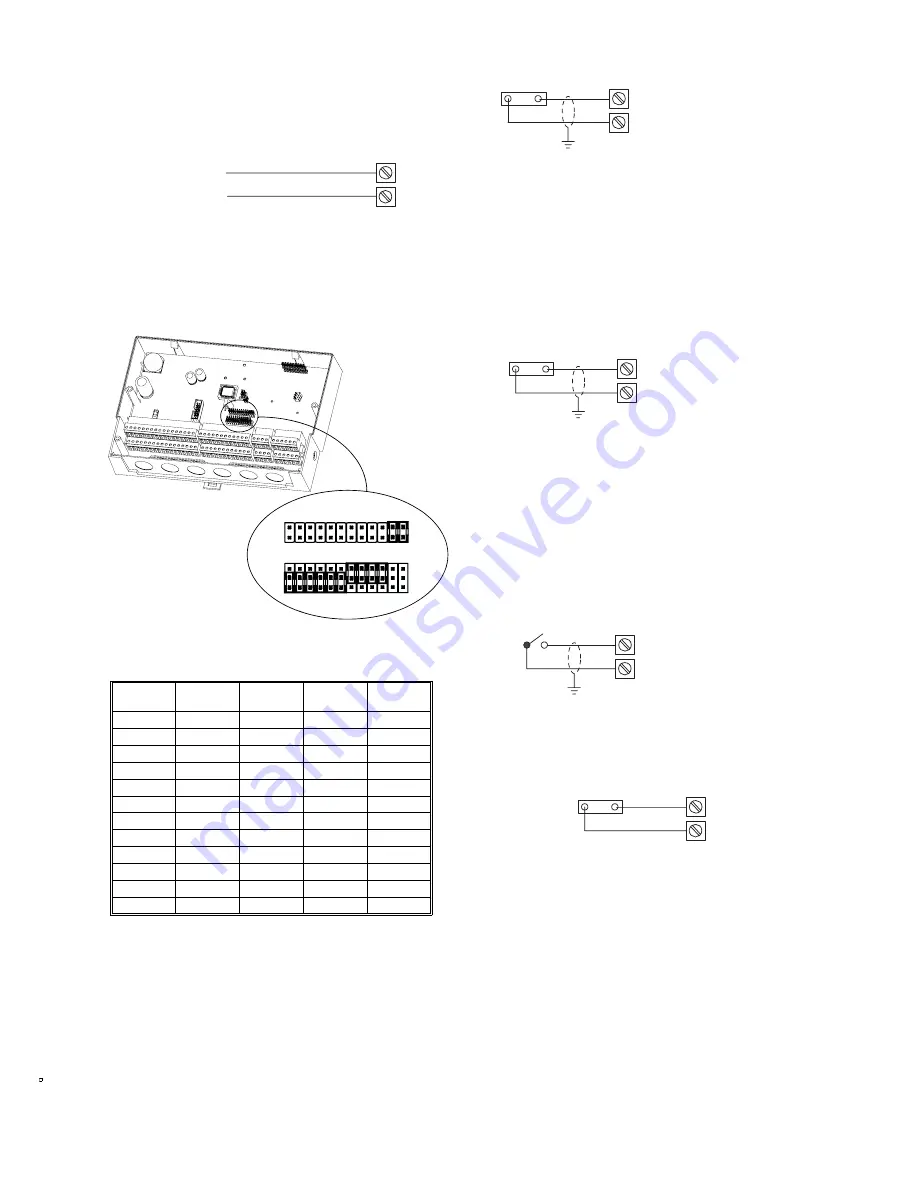

S-Link Sensor Wiring

1.

Review the Precautions section.

2.

Connect unscreened cable to terminals

39

and

78

. Polarity makes

no difference.

See the MN-Sx data sheet (DS 10.000A) for sensor connection

details.

Universal Input (UI) Wiring

UI Configuration

Each UI must be configured as either a Voltage (0 to 10Vdc),

Resistive/Temperature (0-10k

Ω

), or Digital Input. This must match the

usage of the UI in the controller application. Configuration is achieved

by placing the shorting block (jumper) onto the appropriate pins:

Refer to the controller’s 'Controller Definition Drawing' in VisiSat for a

picture of the required UI jumper settings for the controller. Factory

default configuration is shown in the following table. If an input is not

used, leave jumper in the default position.

Note: Each device connected to a UI must use a separate signal and

return conductor. If screened cable is used, connect the screen to

ground at one end only.

Voltage UIs

Note: An externally powered 0 to 10Vdc sensor is required. The input

impedance of a voltage input is 430k

Ω

.

1.

Review the Precautions section.

2.

Connect positive signal wire from 0 to 10Vdc device to desired

input terminal (18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28 or 29).

3.

Connect negative signal wire to one UI common (COM ) terminal

(57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67, 68).

4.

Make certain jumper is in Voltage position.

Resistive (Temperature) UIs

1.

Review the Precautions section.

2.

Connect one wire from the resistive device to desired input

terminal (18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28 or 29). Polarity

is not important.

3.

Connect other wire to UI common (COM ) terminal (57, 58, 59, 60,

61, 62, 63, 64, 65, 66, 67, 68).

4.

Make certain input configuration jumper is in Resistive position.

Digital UIs

Note: Only dry (voltage free) contacts can be monitored. Maximum

count frequency is once every two seconds.

1.

Review the Precautions section.

2.

Connect one wire from field contact to desired input terminal (18,

19, 20, 21, 22, 23, 24, 25, 26, 27, 28 or 29). Polarity is not

important.

3.

Connect other wire to one UI common (COM) terminal (57, 58, 59,

60, 61, 62, 63, 64, 65, 66, 67, 68).

4.

Make certain input configuration jumper is in Digital position.

Wiring for 15Vdc Source

The 15Vdc terminal can provide a 25mA source for use with a DUSF

sensor.Connect load to terminal 38 and 77.

Terminal

Number

Input

Number

Resistive

A

Digital

B

Voltage

C

18

1

Link 1A

19

2

Link 2A

20

3

Link 3A

21

4

Link 4A

22

5

Link 5A

23

6

Link 6A

24

7

Link 7B

25

8

Link 8B

26

9

Link 9B

27

10

Link 10B

28

11

Link 11C

29

12

Link 12C

{

S-Link Sensor

39

78

1 2 3 4 5 6 7

8 9 10 11 12 13 14 15 16 17

18 19 20 21 22 23 24 25 26 2

7 28 29

30 31 32 33

34 35 36 37 38 39

40 41 42 43 44 45 46 47

48 49 50 51 52 53 54 55

56

57 58 59 60 61 62 63 64 65 6

6 67 68

69 70 71 72

73 74 75 76 77 78

B = Digital

C = Voltage

A = Resistive

1 2 3 4 5 6 7 8 9 10 11 12

1 2 3 4 5 6 7 8 9 10 11 12

LK19

LK7

A

B

C

- +

Configure input as Voltage UI

18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28

or 29

57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67

or 68

Refer to the Wiring Routing Rules section.

18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28

or 29

57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67

or 68

Configure input as Resistive UI:

Refer to the Wiring Routing Rules section.

Configure input as Digital UI:

18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28

or 29

57, 58, 59, 60, 61, 62, 63, 64, 65, 66, 67

or 68

Refer to the Wiring Routing Rules section.

15Vdc load

38

77