57

REV:4

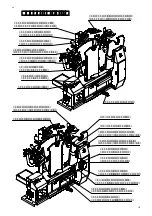

No.

Part Name

Part Number

Q'ty

Remark

201 Cylinder

B0K016

1

Front Press Slide

202

Cylinder Sensor

B5A003

4

203 Joint

C0C054

2

204 Floating Joint

E5L001

1

Cylinder

B1H001

1

Front Press

206 Cylinder Sensor

B5A004

2

207 Speed Controller

C1A024

3

208 Speed Controller

C1A026

1

Cylinder

B2C008

1

Rear Press

210 Cylinder

B0U009

1

Shoulder Press

211 Cylinder Sensor

B5A003

2

212 Speed Controller

C1A012

2

213 Knuckle Joint

B6A004

1

Cylinder

B1A007

1

Neck

215 Joint

C0C161

6

216 Cylinder

B1L003

2

217 Knuckle Joint

B6B007

2

218 Air Combination

D0F008

1

219 Air Gauge

D1C001

1

220 Joint

C0C012

1

2. Air Piping (1)

205

209

214

Содержание LP-570E-V2

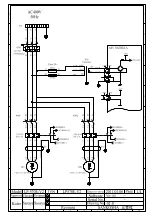

Страница 54: ...54 Motor Operation Diagram 1 Motor Operation Diagram REV 4...

Страница 56: ...56 Air Piping 1 2 Air Piping 1 REV 3 3DLP570E V2 052 2...

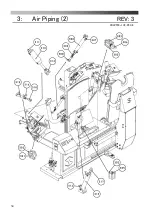

Страница 58: ...58 Air Piping 2 3 Air Piping 2 REV 3 3DLP550J V2 053 6...

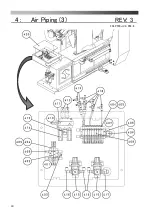

Страница 60: ...60 Air Piping 3 4 Air Piping 3 REV 3 3DLP550J V2 054 6...

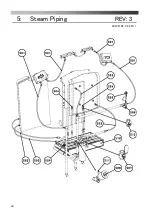

Страница 62: ...62 Steam Piping 5 Steam Piping REV 3 3DLP570E V2 055 1...

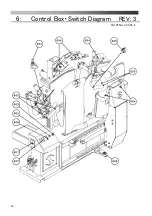

Страница 64: ...64 Control Box Switch Diagram 6 Control Box Switch Diagram REV 3 3DLP550J V2 056 6...

Страница 66: ...66 Cover Diagram 7 Cover Diagram REV 3 3DLP570E V2 057 3...

Страница 69: ......

Страница 70: ......

Страница 71: ......

Страница 72: ......

Страница 73: ......

Страница 74: ......

Страница 75: ......

Страница 76: ...LP 570E V2X Rev 6 2019 6 1 2 B...