S&C Instruction Sheet 766-510

9

Inspection and Handling

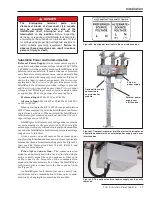

Figure 3. Unbolting a fault interrupter from the shipping

supports.

Figure 4. Removing plastic covers from module bays in base.

Plastic

covers

Figure 5. Placing the dust cover in the module bay.

Figure 6. Set the dust cover on the shelf in the bay.

Uncrating

Before uncrating the unit, note that either side of the

IntelliRupter fault interrupter can be the source side or

the load side. However, when supplied with a three-phase

disconnect, the disconnect is typically placed on the

load side. Also consider whether the IntelliRupter fault

Interrupter has one or two integral power modules. If only

one module is present, make certain the lead from the

module to the bushing faces the source-side.

To uncrate the IntelliRupter fault interrupter, follow

these steps:

STEP 1.

Remove the crate.

(a) Cut the plastic cable ties securing the top of the

shipping crate.

(b) Remove the top, and remove the cartons

containing the protection and control module

and the communication module. Set these aside,

and remove and set aside the waterproof

envelope containing the installation and

operating instructions.

(c) Swing up the two lifting brackets as shown in

Figure 1 and in Figure 2 on page 8—Figure 1 for

the standard IntelliRupter fault interrupter

models and Figure 2 for the compact-crossarm

models.

(d) Attach a suitable sling through the holes in the

lifting brackets. Lift the unit until the sling is just

taut.

(e) Unbolt the fault interrupter base from its skid.

See Figure 3. The 4x4 shipping supports can be

left on if the IntelliRupter fault interrupter is to

be set on the ground for any reason. Do not set the

IntelliRupter fault interrupter on soft or muddy

ground because doing so may damage the

indicators located on the bottom of the fault

interrupter. Slowly and carefully hoist the

IntelliRupter fault interrupter out of the crate.

(f) When the unit is a few feet off the ground, remove

the two SD-6183 plastic dust covers from the

module bays in the base. See Figure 4 for the

location. Store the covers inside the module bay

as shown in Figures 5 and 6. If the modules are

not going to be installed immediately after

mounting the switch to the utility pole, leave the

dust covers in place to protect against wildlife

intrusion into the module bays.

The lifting brackets are permanently attached to the

IntelliRupter fault interrupter base. After installation is

completed, remove the tie wrap and fold down the brackets

to the storage position.

Power

Module