S&C Instruction Sheet 766-510

23

Dielectric Testing

For the convenience of users who normally perform

electrical tests on system components such as IntelliRupter

fault interrupters, appropriate withstand test values are

given in Table 1. These test values are significantly greater

than the normal operating voltage of the IntelliRupter

fault interrupter and are near the flashover voltage of

the equipment. They should be applied only when the

IntelliRupter fault interrupter is completely de-energized

and disconnected from all power sources.

WARNING

The test procedures described below must be

performed by qualified persons who are

knowledgeable in the installation, operation, and

maintenance of overhead electric power distribution

equipment along with the associated hazards.

DANGER

ENERGIZED COMPONENTS. Always consider all

parts live until de-energized, tested, and grounded.

The integrated power module contains components

that can retain a voltage charge for many days

after the IntelliRupter fault interrupter has been

de-energized and can derive a static charge when

in close proximity to a high voltage source. Voltage

levels can be as high as the peak line-to-ground

voltage last applied to the unit. Units that have been

energized or installed near energized lines should be

considered live until tested and grounded.

CAUTION

Keep personnel more than 6.56 feet (2 meters) from

vacuum interrupter during tests.

X-rays can be produced when high voltage withstand

test levels are placed across open contacts.

Exposure to X-radiation can be hazardous to your

health.

WARNING

When performing electrical withstand tests on

IntelliRupter fault interrupter, observe the following

precautions. Failure to observe these precautions

can result in a flashover, injury, and equipment

damage.

STEP 1.

Completely de-energize the IntelliRupter

fault interrupter and disconnect the phase

conductors from all six terminal pads. If the

IntelliRupter fault interrupter is supplied with

the optional wildlife protection feature

(catalog number suffix “-W1” or “-W2”), slide

the tap cover back far enough to gain access

to the terminal pads. Remove the upper and

lower terminal-pad covers to permit the

removal of the phase conductors. Retain the

covers for reuse at the conclusion of the test.

STEP 2.

At each of the six terminal pads, disconnect

the leads for the surge arresters. Make sure

that the surge arrester leads are tied back so

they are at least 8 inches (203 mm) from any

terminal pad.

STEP 3.

At the appropriate terminal pads, disconnect

the lead(s) for the integral power module (or

modules). Ground the lead(s) from the

integral power module (or modules). At the

test voltages specified, damage to the

integral power module (or modules) will

result if they are not disconnected and

grounded.

STEP 4.

Open the IntelliRupter fault interrupters

locally using the Wi-Fi communications link

as described on page 18, or manually by

using a hookstick to pull down on the OPEN

lever. For disconnect-style models, close

the hookstick-operated disconnect.

①

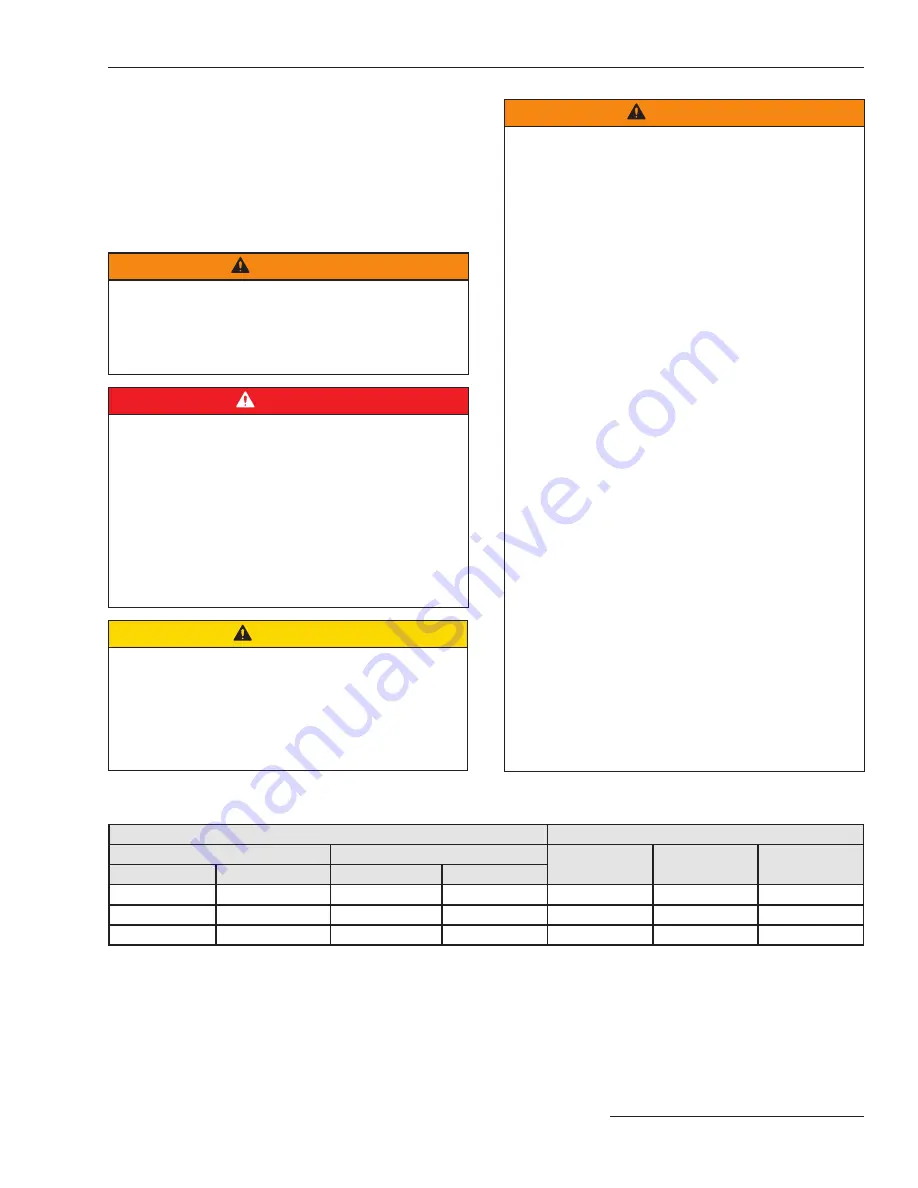

The power frequency withstand test voltages listed in the table are

approximately 80% of the design values for new equipment.

②

These values may be applied from terminal to terminal, or from ter-

minal to ground, for a duration not to exceed one minute.

③

Dc withstand test voltages are given for reference only for users

performing dc withstand tests. The presence of these values does not

imply a dc withstand rating or performance requirement for IntelliRupter

fault interrupters. A dc withstand design test is specified for new equip-

ment because the equipment may be subjected to dc test voltage when

connected to cables. The dc withstand test voltages listed in the table

are approximately equal to the peak of the power frequency withstand

test voltages.

Table 1. Withstand Test Voltages

IntelliRupter Fault Interrupter Rating, kV

Withstand Test Voltage, kV

60 Hz

50 Hz

60-Hz, RMS

①②

Dc

③

Impulse (BIL)

Min.

Max.

Min.

Max.

11.43

15.5

10

17.5

48

67

110

18.81

27

20

24

48

67

125

23.8

38

29.7

38

56

79

170