Fast Track Troubleshooting

Models:

WF209ANW/XAA

Publication # tsWF209 Revision Date 08/13/2010

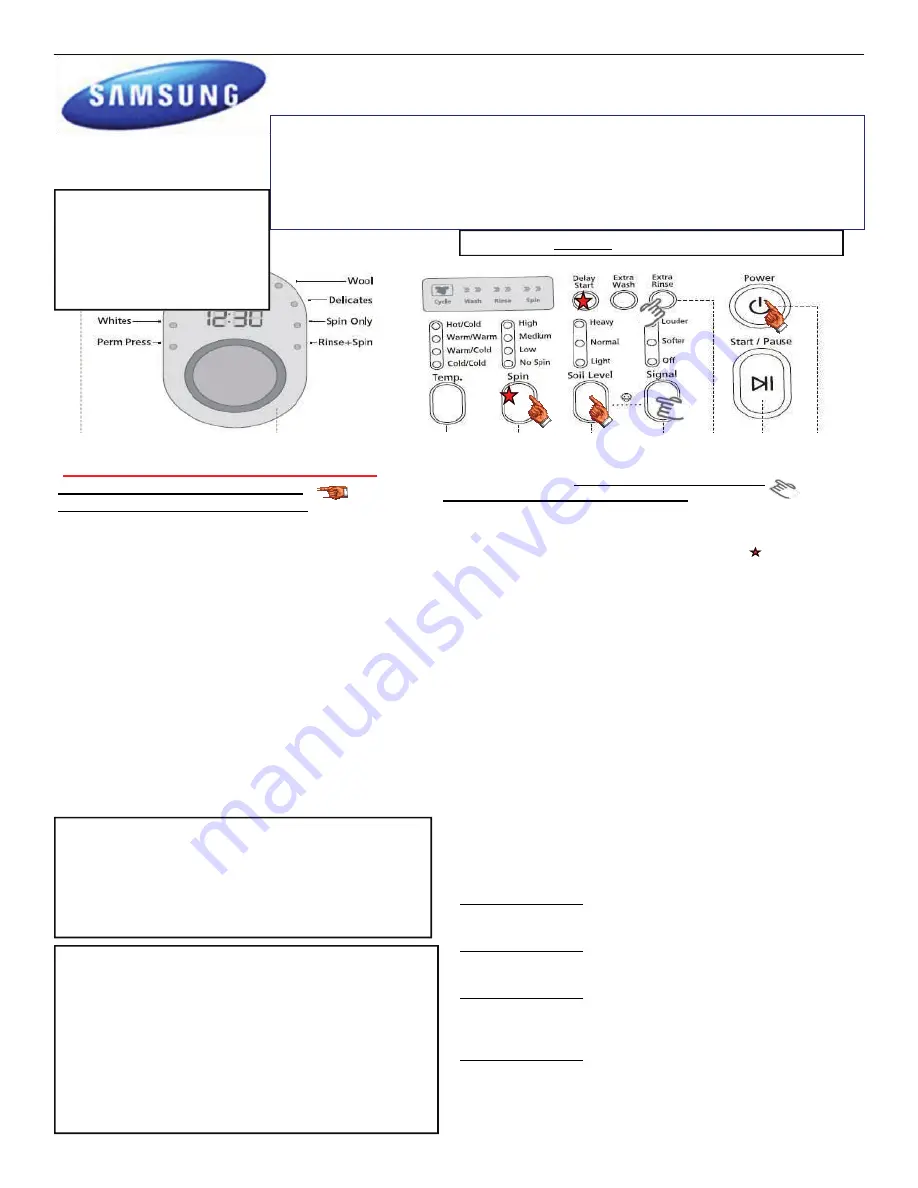

Quick Test Mode

Note: This test erases all faults and memory

:

To enter press Spin,

Soil, & Power

simultaneously with the power off.

1. All LED’s light up and the washer beeps as it

enters the Quick Test Mode.

2. The unit displays the software version.

3. After the displaying the software version, turn

Jog dial CCW Once, or Twice (showing zeros) on

some units

If EEEE is displayed the PCB ass’y is defective.

Press

Temp Key (press spin to lock door if neces-

sary)

to cycle through the Water Valves circuit test in

this order: Cold Main, Bleach, Cold Main & Bleach for

Fabric Softener, Hot, then off.

Press

Soil Key

to test the motor

Press

Spin

to test Door Lock/Unlock circuit.

Press

Signal Key

to test the Pump

Service Mode:

This mode allows more detailed operation tests and trouble-

shooting, to enter press

Signal & Extra Rinse

simultaneously with the power on.

While in Service Mode the following tests can be performed:

Quick Spin Test =

Delay Start & Spin: This

accelerates

the drum motor from 0 to maximum RPM over a few min-

utes.

Note: Stay with the washer during this test, out of bal-

ance detection is bypassed and the door may not lock.

Press the Start/Pause button during the test to hold its spinning

speed for 10 minutes before going back to Quick Spin Test

Mode.

Cycle Count =

Press the

Signal

button to see how many times

the unit was used

Soft Ware # =

Press the

Soil

button to see the software version

information

Fast Time Down =

Press the

Temp

button to advance to the

next cycle

Fault Code Test =

Press the Spin button to view the stored fault

codes – then turn Dial to view error codes (Push Start/Pause

while the code is displayed to view the number of cycles since

the error occurred)

Peripheral (Main PCB) input Tests

1.

Select Extra Wash. Then turn the Dial

so that the

Heavy

is

turned on. Next, press the Start/Pause Key. The Water

Temperature will be displayed in Fahrenheit.

2.

Select Extra Wash. Then turn the Dial

so that the

White

is

turned on. Next, press the Start/Pause Key. The door status will

be displayed (OP if open, CL if closed).

3.

Select Extra Wash. Then turn the Dial

so that the

Perm.

Press

is turned on. Next, press the Start/Pause Key. The door

lock Switch status will be displayed (UL if unlocked, Lo if

locked).

4.

Select Extra Wash. Then turn the Dial

so that the

Wool

is

turned on. Next, press the Start/Pause Key. The Water

Frequency will be displayed.

IMPORTANT SAFETY NOTICE

–

“For Technicians Only”

This service data sheet is

intended for use by persons having electrical, electronic, and mechanical experience

and knowledge at a level generally considered acceptable in the appliance repair trade.

Any attempt to repair a major appliance may result in personal injury and property

damage. The manufacturer or seller cannot be responsible, nor assume any liability for

injury or damage of any kind arising from the use of this data sheet.

Location considerations

Do not install your washer in areas where

water may freeze, since your washer will

always maintain some water in its water valve,

pump, and hose areas. This can cause

damage the belts, the pump, hoses and other

components.

Operating temperature should

be above 60°F/16°C.

EEPROM Clear Check

Power off, Press Delay Start, Signal and Power Key at

the same time. Good = Good Fail = FAiL

All memory will be cleared, including Fault Codes

This should be done when a new Main PCB is

installed

Please Note:

There are

two Versions of this model,

verify you are ordering the

correct parts for the Version

you are servicing.

1

Содержание WF209ANW/XAA

Страница 2: ...WF209 2 ...