33

ENGLISH

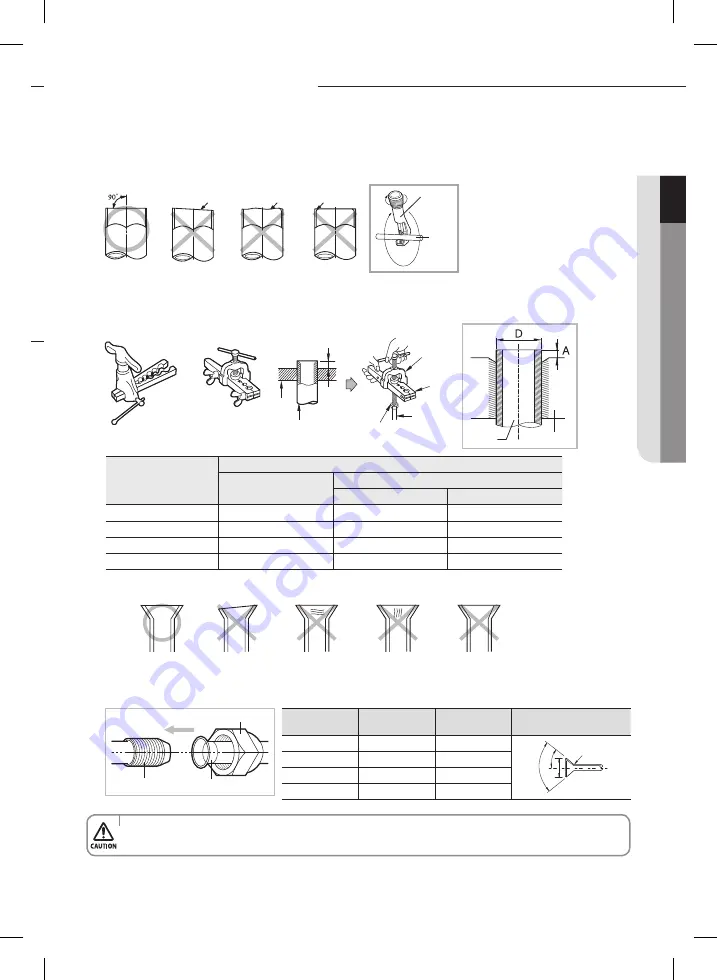

Cutting/flaring the pipe

1. Make sure that you prepared the required tools. (pipe cutter, reamer, flaring tool and pipe holder)

2. If you want to shorten the pipe, cut it using a pipe cutter ensuring that the cut edge remains at 90° with the side of the

pipe. There are some examples of correctly and incorrectly cut edges below.

3. To prevent a gas leak, take care not to allow burrs to enter the pipe and clean the flare.

Oblique

Rough

Burr

Pipe

cutter

Pipe

Outer diameter (mm)

A(mm)

Flare tool for

R410A clutch type

Conventional flare tool

Clutch type

Wing nut type

ø6.35 mm

0~0.5

0~0.5

1.5~2.0

ø9.52 mm

0~0.5

0~0.5

1.5~2.0

ø12.70 mm

0~0.5

0~0.5

1.5~2.0

ø15.88 mm

0~0.5

0~0.5

1.5~2.0

4. Carry out flaring work using flaring as shown below.

Pipe

Flare

Flaring tool

Clutch type

Wing nut type

A

Die

Copper pipe

York

Die

Copper

pipe

Flare nut

Indoor outlet pipe

Connecting pipe

Flare nut

5. Check if you flared the pipe correctly (see examples of incorrectly flared pipes below).

6. Align the pipes and tighten the flare nuts first manually and then with a torque wrench, applying the following torque.

Correct

Uneven

Thickness

Cracked

Damaged

Surface

Inclined

Outer diameter

(mm)

Connection

Torque(kgf•cm)

Flare dimen-

sion (mm)

Flare shape

(mm)

ø6.35 mm

145~175

8.70~9.10

ø9.52 mm

333~407

12.80~13.20

ø12.70mm

505~615

16.20~16.60

ø15.88 mm

630~769

19.30~19.70

R 0.4~0.8

90

° ±

2°

45

° ±

2°

• Purge pipe work with oxygen free nitrogen while brazing.

RHF050KHEA_IB,IM_E_32885-3.indd 33

2011-10-12 오후 5:30:33