Disassembly and Reassembly

Samsung Electronics

1-61

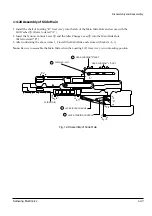

1-5 Cleaning and Lubrication

1-5-1 Cleaning Tape Mechanism

Periodic cleaning of the tape mechanism is necessary.

To clean the following parts, use patch and solvent :

1. Capstan Shaft

2. All tape guide posts

3, Clutch Pulley

4. Pinch roller

5. Belt Capstan

6. Capstan Motor Pulley

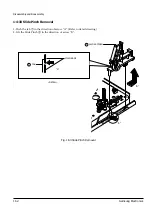

1-5-2 Cleaning of Rotating and Stationary

Heads

To clean video heads, full erase head, and the

audio/control (A/C) head we recommend using a

head cleaning kit and solvent.

Note :

When cleaning video heads, move the

cleaning stick in the direction of head

rotation (wiping in a vertical direction may

damage the heads.)

Press a chamois cloth which has been dipped in

cleaning fluid lightly against the rotating Cylinder

AssÕy. Clean slowly by rotating the Upper Cylinder

AssÕy by hand.

Note :

Never turn the Motor on when cleaning.

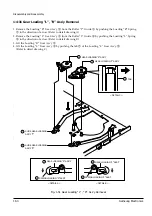

1-5-3 Lubrication of Tape Mechanism

The tape transport mechanism is properly lubricated

at the factory. In normal use cycles, and with average

environmental conditions, additional lubrication

should not be required during the first year of

operation.

Depending on the frequency of use and environmen-

tal conditions, periodic lubrication may be required.

When lubricating, first remove the old lubricant, then

sparingly apply new lubricant. Excessive lubricant is

transferred to other assemblies, malfunction will

result.

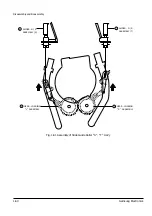

Use grease on the following parts every 1,000 hours.

(See exploded view for location) :

1. Between base pole assembly (L, R) and main base

2. Gear Loading L, R

3. Slide Main

4. Lever Shift

5. Gear Master

6. Lever Slide Pinch

7. Pinch Roller

8. Slide Pinch

9. Base Cylinder

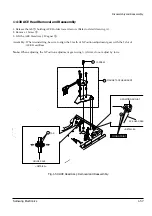

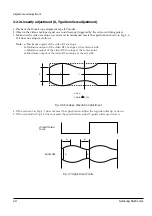

Oil may be required for the following parts after

1,000 hours. (See exploded view for location) :

Main Base

1. Arm Tension molding

2. Shaft Reel Disk L, R

3. Shaft Gear Relay S, T

4. Shaft Idler

5. Shaft Clutch

Other parts which are not listed above do not require

lubrication, except when parts are replaced.

Use appropriate oil or grease as indicated on the

exploded view.