www.samsungehs.co.uk

©G Hendra April 2015

6

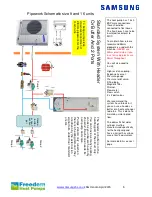

Other components you need to supply and fit:

An expansion vessel, pressure gauge, pressure relief valve and filling

loop

Most heating engineers use a robokit with the appropriate size expansion

vessel; this is sized exactly the same way as when using a boiler.

Pump

Your pump needs to supply 20l/min for the 9kW and 30l/min for the 16kW unit.

The static resistance through the unit is 10kPa for the 9kW and 15kPa for the

16kW unit. The flow meter has a resistance of around

5kPa

The cylinders (Gledhill) have a static resistance of 5kPa for the heat pump coil

and 19kPa for the solar coil.

The total resistance of the components will be approximately 39kPa for the size

9 unit and if the cylinder is piped using both coils and approximately 44kPa for the size 16

unit.

Flow switch and flow meter

The unit requires 17L / min flow at all times, if you don’t achieve this

E911 error will occur to check this flow switch is installed. The flow

switch comes with the control box.

The flow Switch MUST be installed in either horizontally or vertically

with at least 150mm of straight pipe either side, connection is 1” female BSP. The wire is 2m

long and needs to connect into the wiring station. This wire can be extended to suit. We

recommend a flow meter is installed into the flow side of the flow switch as per the photo.

Adaptors may be required to enable this join. The flow switch is not IP65 rated (weatherproof)

and so must not be installed externally.

Diverter valves

If you require domestic hot water and heating, diverter valves are required, you

need to supply these.

Water Filter

In all cases a filter with strainer needs to be installed in the return to the heat pump. A

magnetic filter

must

also be installed in the return to the unit. The filters ensure that

debris/foreign materials do not cause damage to the heat exchanger in the unit voiding

warranties.

Glycol

A propylene glycol mixture must be utilized to prevent freezing of the water within the system.

It is important that the glycol concentration is adequate to protect the unit in case of power

failure in very cold conditions. If the unit freezes up there will be no warranty. Manufacturer

dependant, a mix of around 25% should suffice.

Buffer vessels, heat exchangers and low loss headers

You don’t have to use a buffer vessel on a Samsung but we do need a minimum flow rate of

17l/min and have a circulating volume of over 20 Litre. To achieve this is much easier if you

break the system in two with a header, a buffer or a heat exchanger.

Bypass Valve

If you don’t use a header buffer or heat exchanger you must install a bypass

valve in the heating circuit as far away from the heat pump as possible. The

bypass valve enables flow to be maintained as the trv’s shut down at all times to

prevent unit flow fault.

The Cylinder:

The cylinder needs to be installed less than 15m from the control box to allow for the

temperature sensor cable. Note the size and weight of the cylinder. Full installation

instructions are included with the cylinder.

Cylinders can be used IF the coil area is more than 2.5m^2. Smaller coils are not acceptable

and cannot be used. Please do not attempt to utilize a standard central heating, non-heat

pump optimized cylinder. Cylinders can be pressurised or open vented.