2023_02_28-09:30

EN

3

R. 02/23 853 803

SAMOA Industrial, S.A. · Pol. Ind. Porceyo, I-14 · Camino del Fontán, 831 · 33392 - Gijón - Spain · Tel.: +34 985 381 488 · www.samoaindustrial.com

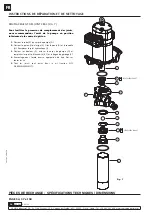

K

I

L

A

B

C

D

E

J

F

G

H

WARNINGS

Compressed air powered reciprocating piston pump. This high capacity

demand pump is compatible with mineral and synthetic oils and

suitable for large installations with long length piping supplying several

fluid outlets simultaneously.

This pump can be mounted on the wall, with wall mounting bracket

(Part. No. 360132).

• The use of non compatible fluids may cause damage in the pump

and serious personal injury. This equipment is not intended for use

with fluids that fall within the Group 1 fluid as defined that are

explosive, extremely flammable, highly flammable, flammable, very

toxic, toxic, oxidizing or where the vapor pressure if greater than 0.5

bar (7 psi) above the pressure atmospheric at the maximum

allowable temperature.

• The pump generates high or very high pressures. Do not exceed the

maximum air inlet pressure of 12 bar (170 psi).

• A direct hit against the human body may result in an injury.

• This unit may have stored pressure, release all pressure and

disconnect from any fluid systems before servicing. To ensure safe

INSTALLATION

operation of this unit, all service work should be by qualified

personnel only.

• When not in use, be sure to shut off the air supply to avoid accidents.

• Do not alter or modify this equipment. Use genuine components

provided from Samoa Industrial, S.A. Any unauthorized tampering

with this equipment, improper use, poor maintenance or removal of

identifications labels may invalidate the guarantee.

• All fittings in the system connected to the outlet of the pump should be

suitable for the maximum possible pressure generated by the pump/air

motor. If the systems cannot be designed to take the maximum pressure

produced by the pump, safety valves or diverter valves should be fitted.

• User must respect the surface temperature considerations in explosive

atmospheres. This manual specifies conditions in this regard. The ATEX

marking states the maximum temperature that the equipment can reach

in use, which will depend on that of the oil and/or ambient, and should

be taken into account.

WARNING:

Read all instruction manuals, tags, and labels

before operating the equipment. This equipment is for

professional use only.

!

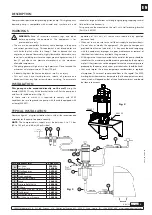

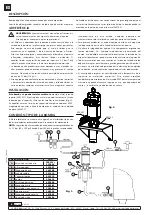

This pump can be mounted directly on the wall,

using the

bracket (360132). Firmly fix the bracket to the wall. Put the pump on it

and fix with included screws (Fig. 2).

In those cases in which it is required to comply with ATEX

conditions, be sure to ground the pump with the cable equipped with

a clamp (534907).

Fig. 2

TYPICAL INSTALLATION

Please see figure 3, a typical installation shown with all the recommended

accesories for the pump to operate correctly.

NOTE:

The compressed air supply must be between 2 to 12 bar

(40 to 180 psi), and 6 bar (80 psi) is ideal.

Fig. 3

POS. DESCRIPTION

PART NO.

A

Ball Valve,

Low Pressure

239004

B

Filter/Regulator

241001

C

Air hose

362100

D

Quick coupling

251412

E

Connection nipple

255312

F

Pump

536330

G

Pressure Relief Valve

609008

H

Oil hose

362303

I

Ball Valve, Medium Pressure

950303

J

Wall bracket

360132

K

Oil suction hose

367003

L

Ball Valve, Low Pressure

950306

B

A

DESCRIPTION

360132

534907