Operating manual

Rear disc mowers with central suspension

- with hydro-pneumatic or spring suspension

- 3 0 -

6.

With re-cultivated pastures during first mowing or after long lasting heavy rains it is necessary

to reduce the pressure of the bar on the ground by adjusting the spring or the hydro-pneumatic

suspension.

ATTENTION:

The mower could leave a small furrow in the middle of the cut because of

the push of the air resulting from the cutting disc rotating in opposite

directions.

WARNING:

Tilting the mower back is forbidden as it wil cause faster wear or even

damage of the cutterbar.

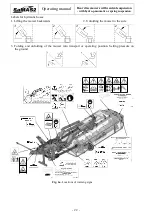

5.5.2.

Mower positioning during directional changes

Raise the mower using the hydraulic lift (Position 2 Fig. 3) and turn around. The height of

the raised mower is enough to drive over mowed grass without additionally raising the mower on

the TPH of the tractor.

5.5.3.

Mower clogging

When operating the mower pay attention to variable conditions on field, which may influence

the mower clogging, such as: terrain unevenness, height and density of grass as well as other

objects in the grass. In order to avoid clogging, mowing speed should be adjusted to the mentioned

conditions. In order to remove the machine clogging, cutterbar should be lowered onto the ground

while the drive must be disconnected with ignition key off.

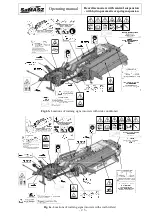

5.6.

Preparing the mower for transport

The following is required to prepare the mower connected to a tractor for transport -

movement on public roads:

lift the mower with tractor hydraulic lift onto the tractor links until the lower lift pins of

the mower 3-point linkage frame are raised above the ground:

a)

about 15 cm in case of KT 341 (H) and KT 340 (H),

b)

about 40 cm in case of other models of KT (Fig. 15),

lower the transport height on the tractor links, so it does not exceed 4 m,

lift the support leg S (Fig. 9),

the mower is equipped with service-free transport lock (Fig. 13). Non-locking the lock may

cause damage to PTO shafts,

lift the 3-point linkage frame vertically with hydraulic cylinder and lock the lock Z (Fig. 11),

Fig. 11. Z – Locking bar

Z